Nissan Sentra Service Manual: Flywheel

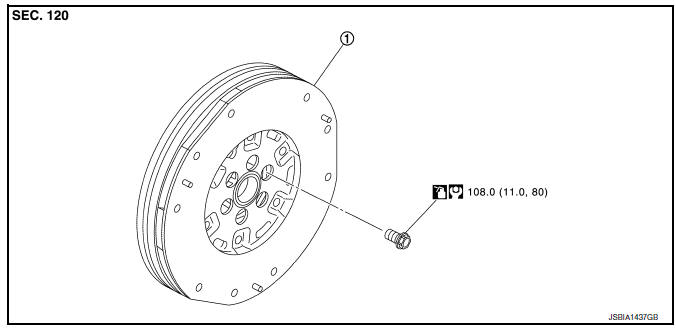

Exploded View

- Flywheel

Removal and Installation

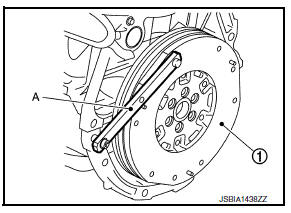

REMOVAL

- Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the engine. Refer to TM-28, "Exploded View".

- Remove flywheel.

- Secure flywheel (1) using Tool (A), and remove bolts using suitable tool.

Tool number : KV11105210 (J-44716)

CAUTION:

- Do not disassemble flywheel.

- Do not place flywheel with signal plate facing down.

- When handling signal plate, take care not to damage or scratch.

- Handle signal plate, do so in a manner that prevents it from becoming magnetized.

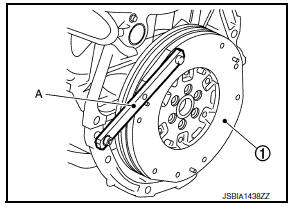

INSTALLATION

- Install flywheel.

- Secure flywheel (1) using Tool (A), and install bolts.

Tool number : KV11105210 (J-44716)

CAUTION:

Be careful not to damage or scratch the contact surface of flywheel.

Inspection

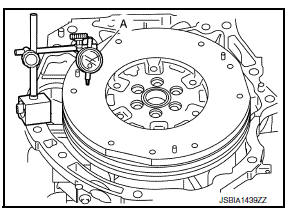

FLYWHEEL DEFLECTION

- Measure the deflection of flywheel contact surface to torque with a dial indicator (A).

- Measure the deflection at 210 mm (8.27 in) diameter.

Limit : 0.45 mm (0.0177 in) or less.

- If measured value is out of the standard, replace flywheel.

- If a trace of burn or discoloration is found on the surface, repair it with sandpaper.

MOVEMENT AMOUNT OF FLYWHEEL

CAUTION:

Do not disassemble double mass flywheel.

Movement Amount of Thrust (Fore-and-Aft) Direction

- Measure the movement amount of thrust (fore-and-aft) direction when 100 N (10.2 kg, 22 lb) force is added at the portion of 125 mm (4.92 in) radius from the center of flywheel.

Standard : 1.8 mm (0.071 in) or less

- If measured value is out of the standard, replace flywheel

Movement Amount in Radial (Rotation) Direction

Check the movement amount of radial (rotation) direction with the following procedure:

- Install clutch cover bolt (1) to clutch cover hole, and place a torque wrench (A) on the extended line of the flywheel (2) center line.

- Tighten bolt at a force of 9.8 NВ·m (1.0 kg-m, 87 in-lb) to keep it from loosening.

- Put a mating mark on circumferences of the two flywheel masses without applying any load (Measurement standard points).

- Apply a force of 9.8 NВ·m (1.0 kg-m, 87 in-lb) in each direction, and mark the movement amount on the mass on the transaxle side.

- Measure the dimensions of movement amounts (A) and (B) on circumference of the flywheel on the transaxle side.

Limit : 33.2 mm (1.307 in) or less.

- If measured value is out of the standard, replace flywheel.

Drive plate

Drive plate

Exploded View

Pilot converter

Drive plate

Reinforcement plate

Chamfered

Removal and Installation

REMOVAL

Remove the engine and the transaxle assembly from the vehicle, and

...

Other materials:

Cup holders

CAUTION

Avoid abrupt starting and braking when

the cup holder is being used to prevent

spilling the drink. If the liquid is hot, it

can scald you or your passenger.

Use only soft cups in the cup holder.

Hard objects can injure you in an

accident.

Do not use bottle holder for any ...

Power generation voltage variable control system

System Diagram

System Description

Power generation variable voltage control system has been adopted. By varying

the voltage to the generator,

engine load due to power generation of the generator is reduced and fuel

consumption is decreased.

NOTE:

When any malfunction is detected in the ...

Automatic anti-glare rearview mirror (if so equipped)

The inside mirror is designed so that it automatically

dims according to the intensity of the headlights

of the vehicle following you. The automatic

anti-glare feature is activated when the ignition

switch is in the ON position.

NOTE:

Do not hang any objects over the sensors

1 or apply gl ...