Nissan Sentra Service Manual: Diagnosis and repair work flow

Work Flow

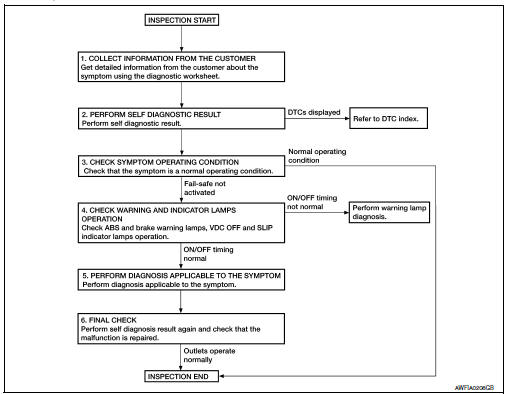

OVERALL SEQUENCE

DETAILED FLOW

1.COLLECT INFORMATION FROM THE CUSTOMER

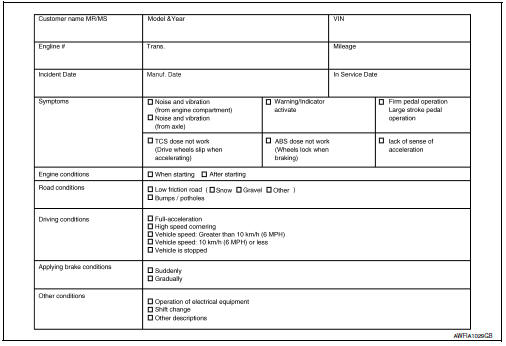

Get detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred) using the diagnostic worksheet. Refer to BRC-52, "Diagnostic Work Sheet".

>> GO TO 2.

2.PERFORM SELF DIAGNOSTIC RESULT

Perform self diagnostic result. Refer to BRC-31, "CONSULT Function (ABS)".

Are any DTCs displayed? YES >> Refer to BRC-43, "DTC Index".

NO >> GO TO 3.

3.CHECK SYMPTOM OPERATING CONDITION

Check that the symptom is a normal operating condition. Refer to BRC-105, "Description".

Is the symptom a normal operating condition? YES >> Inspection End.

NO >> GO TO 4.

4.CHECK WARNING AND INDICATOR LAMPS OPERATION

Check ABS and brake warning lamps, and VDC OFF and SLIP indicator lamps operation. Refer to MWI-8, "METER SYSTEM : System Description".

Is ON/OFF timing normal? YES >> GO TO 5.

NO >> Perform warning lamp diagnosis. Refer to BRC-94, "Component Function Check" (ABS warning lamp), BRC-95, "Component Function Check" (brake warning lamp), BRC-96, "Component Function Check" (VDC OFF indicator lamp) or BRC-97, "Component Function Check" (SLIP indicator lamp).

5.PERFORM DIAGNOSIS APPLICABLE TO THE SYMPTOM

Perform diagnosis applicable to the symptom. Refer to BRC-98, "Symptom Table".

>> GO TO 6.

6.FINAL CHECK

Perform self diagnostic result again, and check that the malfunction is repaired. After checking, erase the self diagnosis memory. Refer to BRC-31, "CONSULT Function (ABS)".

>> Inspection End

Diagnostic Work Sheet

Additional service when replacing abs actuator and electric unit (control unit)

Description

When replacing the ABS actuator and electric unit (control unit), perform steering angle sensor neutral position adjustment. Refer to BRC-54, "Work Procedure".

Basic inspection

Basic inspection

...

Adjustment of steering angle sensor neutral position

Adjustment of steering angle sensor neutral position

Description

Refer to the table below to determine if adjustment of steering

angle sensor neutral position is required.

×: Required –: Not required

Work Procedure

ADJUSTMENT OF ST ...

Other materials:

Clutch master cylinder

Exploded View

Reservoir hose

Reservoir tank

Clutch master cylinder

Removal and Installation

REMOVAL

CAUTION:

Keep painted surface on the body or other parts free of clutch

fluid. If it spills, wipe up immediately

and wash the affected area with water.

Do not disassemble c ...

Intake manifold tuning system

INTAKE MANIFOLD TUNING SYSTEM : System

Description

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

This system switches the length of intake air path according to the

low-to-medium speed range or high speed

range. Torque is increased in the low-to-medium speed range and the engine

output is improved ...

Operating tips

When the engine coolant temperature and

outside air temperature are low, the air flow

from the foot outlets may not operate for a

maximum of 150 seconds. However, this is

not a malfunction. After the coolant temperature

warms up, air flow from the foot outlets

will operate normally.

...