Nissan Sentra Service Manual: Water hose

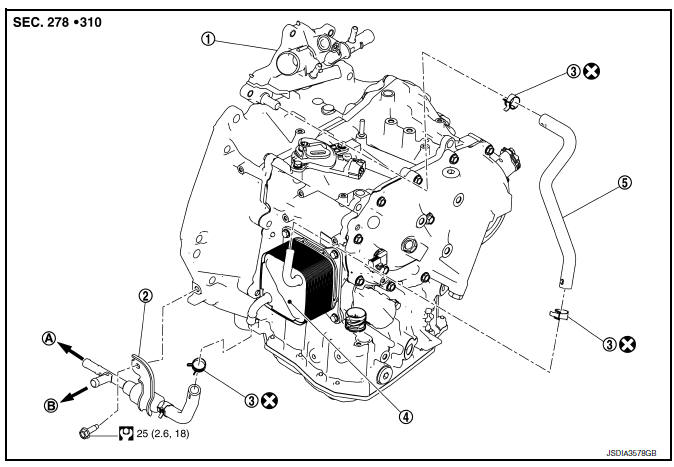

Exploded View

- Water outlet

- Heater thermostat assembly

- Hose clamp

- CVT oil warmer

- Water hose

- To thermostat housing

- To engine oil cooler

: Always replace after every

: Always replace after every

disassembly.

: NВ·m (kg-m, ft-lb)

: NВ·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down and turning it all the way.

CAUTION:

Perform these steps after the coolant temperature has cooled sufficiently.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

- Remove the engine under cover. Refer to EXT-31, "ENGINE UNDER COVER : Removal and Installation".

- Drain engine coolant from radiator. Refer to CO-12, "Changing Engine Coolant".

- Remove water hose and heater thermostat assembly.

INSTALLATION

Installation is in the reverse order of removal.

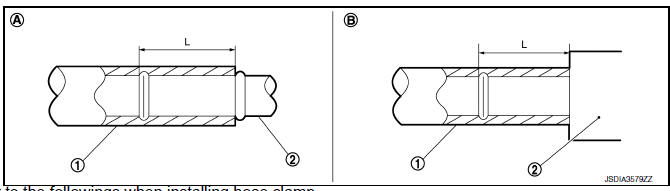

- Refer to the following when installing water hoses.

| Water hose (1) | Installation side tube (2) | Direction of paint mark | Hose insertion depth (L) |

| Heater thermostat assembly | CVT oil warmer | Frontward | (A): 27 mm (1.06 in) (Hose end reaches the 2-stage bulge.) |

| Water hose | CVT oil warmer | Frontward | |

| Water outlet | Frontward | B): 27 mm (1.06 in) (Hose end reaches the end of water outlet tube.) |

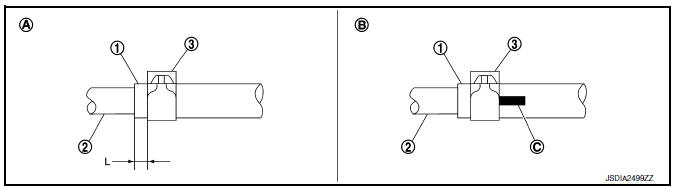

- Refer to the followings when installing hose clamp.

CAUTION:

- Do not reuse hose clamp.

- Hose clamp should not interfere with the bulge of fluid cooler tube.

| Water hose (1) | Installation side tube (2) | Hose clamp (3) | |

| Direction of tab | Clamping position | ||

| Heater thermostat assembly | CVT oil warmer | Frontward | (B): Align with the end of paint mark (C) |

| Water hose | CVT oil warmer | Frontward | (A): 5 – 7 mm (0.20 – 0.28 in) (L) from hose end |

| Water outlet | Frontward | ||

Inspection

INSPECTION AFTER REMOVAL

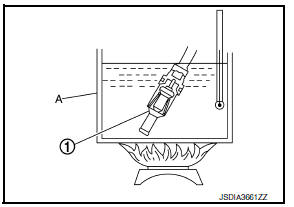

Heater Thermostat

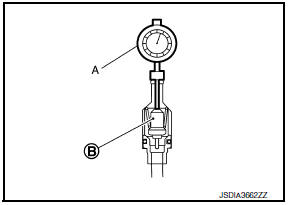

- Fully immerse the heater thermostat 1 in a container (A) filled with water. Continue heating the water while stirring.

- Continue heating the heater thermostat for 5 minutes or more after bringing the water to a boil.

- Quickly take the heater thermostat out of the hot water, measure the heater thermostat within 10 seconds.

- Place dial indicator (A) on the pellet (B) and measure the elongation from the initial state.

Standard : Refer to TM-289, "Heater Thermostat".

- If out of standard, replace heater thermostat.

INSPECTION AFTER INSTALLATION

Start the engine, and check the joints for coolant leakage.

Differential side oil seal

Differential side oil seal

Exploded View

Transaxle assembly

Differential side oil seal (left side)

Differential side oil seal (right side)

: Vehicle front

: Always replace after every

disassembly.

: Genuin ...

Plug

Plug

Description

Replace the O-ring if oil leakage or exudes from the plug.

Exploded View

Plug

O-ring

O-ring

Plug

: Always replace after every

disassembly.

: NВ·m (kg-m, ft-lb)

...

Other materials:

Latch system for children

Exploded View

LATCH bracket (RH)

LATCH bracket (LH)

Seat belt buckle anchor bracket

Front

Removal and Installation

REMOVAL

Remove the rear seat cushion assembly. Refer to SE-23, "Removal and

Installation - Seat Cushion

Assembly"

Remove the rear seatback assemb ...

Audio system voice commands

To access the audio system voice commands:

Press the button.

Say “Audio”

Speak a command from the following available

commands:

Play (AM, FM, etc.)

Allows user to select radio band

Tune AM (number)

Allows user to tune directly to a desired AM

frequency

Tune FM (number)

...

P2004 Intake manifold runner control valve

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P2004

TUMBLE CONT/V

(Intake manifold runner control

stuck open bank 1)

The target angle of intake manifold runner

control valve c ...