Nissan Sentra Service Manual: System description

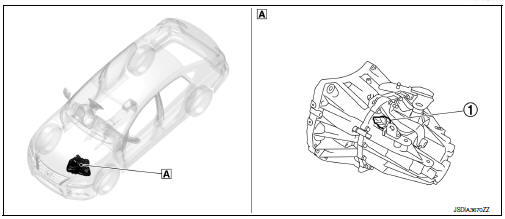

COMPONENT PARTS

Component Parts Location

- Transaxle assembly

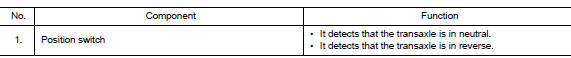

STRUCTURE AND OPERATION

Sectional View

- 3rd input gear

- 3rd-4th synchronizer hub assembly

- 4th input gear

- 5th input gear

- 5th-6th synchronizer hub assembly

- 6th input gear

- Transaxle case

- 6th main gear

- 5th main gear

- 4th main gear

- 3rd main gear

- 2nd main gear

- 1st-2nd synchronizer hub assembly

- 1st main gear

- Differential

- Final gear

- Mainshaft

- Input shaft

- Clutch housing

- Reverse idler shaft

- Reverse input gear

- Reverse output gear

System Description

Triple-cone synchronizer

Triple-cone synchronizers are adopted for the 1st and the 2nd gears to reduce operating force of the shifter lever.

- 1st main gear

- 1st-2nd coupling sleeve

- Insert key

- Outer baulk ring

- 2nd main gear

- Synchronizer cone

- Inner baulk ring

- 1st-2nd synchronizer hub

Reverse gear noise prevention function (synchronizing method)

Reverse gear assembly consists of reverse input gear, return spring, reverse baulk ring, and reverse output gear. When the shifter lever is moved to the reverse position, the construction allows smooth shift operation by stopping the reverse idler shaft rotation by frictional force of synchronizer.

- Reverse fork rod

- Reverse output gear

- Return spring

- Reverse baulk ring

- Reverse input gear

Preparation

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tools

...

DTC/Circuit diagnosis

DTC/Circuit diagnosis

POSITION SWITCH

BACK-UP LAMP SWITCH

BACK-UP LAMP SWITCH : Component Inspection

1.CHECK BACK-UP LAMP SWITCH

Disconnect position switch harness connector. Refer to TM-21, "Removal

and In ...

Other materials:

Symptom diagnosis

HEATER AND AIR CONDITIONING SYSTEM

CONTROL SYMPTOMS

Diagnosis Chart By Symptom

Note:

Perform the self-diagnoses with consult before performing the symptom

diagnosis. If dtc is detected, perform

the corresponding diagnosis.

INSUFFICIENT COOLING

Description

Symptom

Insufficient ...

Preparation

Special Service Tools

NOTE:

The actual shapes of Kent-Moore tools may differ from those of special

service tools illustrated here.

Commercial Service Tools

...

P2138 APP Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2138 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643. Refer to

EC-353, "DTC Logic".

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

...