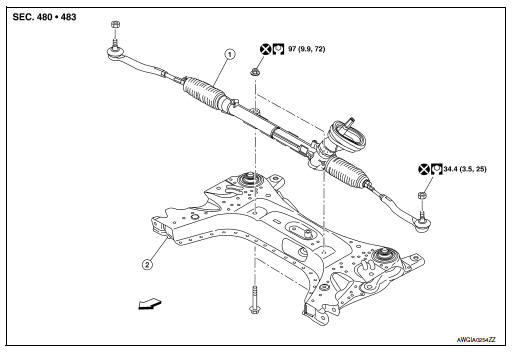

Nissan Sentra Service Manual: Steering gear and linkage

Exploded View

REMOVAL

-

Steering gear assembly

-

Front suspension member

Front

Front

Removal and Installation

REMOVAL

-

Set steering wheel to the straight-ahead position.

-

Remove floor cover (1).

-

Lower shaft assembly (2).

-

Remove the lower shaft assembly bolt and position the lower shaft assembly out of the way. Refer to ST- 12, "Removal and Installation".

CAUTION:

-

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steering gear assembly. Always fix the steering wheel using string to avoid turning.

-

Place a matching mark on both intermediate shaft and steering gear assembly before removing intermediate shaft.

-

Remove wheels and tires using power tool. Refer to WT-47, "Adjustment".

-

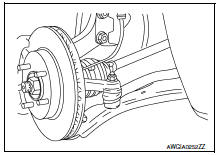

Remove steering outer socket from steering knuckle so as not to damage ball joint boot using Tool.

Tool number : HT72520000 (J-25730-A)

CAUTION:

Temporarily tighten the nut to prevent damage to threads and to prevent the Tool from a sudden drop.

-

Remove front suspension member. Refer to FSU-16, "Removal and Installation".

-

Remove steering gear assembly from front suspension member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steering gear assembly. Always fix the steering wheel using string to avoid turning.

-

Perform final tightening of nuts and bolts on each part under unladen conditions with tires on level ground when removing steering gear assembly.

-

Check wheel alignment. Refer to FSU-7, "Adjustment".

-

Rotate steering wheel to check for decentered condition, binding, noise or excessive steering effort.

-

Do not reuse steering outer socket nut and steering gear assembly nut.

-

Perform neutral position steering angle adjustment. Refer to BRC-54, "Work Procedure".

Steering column

Steering column

Exploded View

Steering column assembly

Slide plates

lower shaft assembly

Removal and Installation

REMOVAL

CAUTION:

While removing the steering column assembly, do not ...

Unit disassembly and assembly

Unit disassembly and assembly

Steering gear and linkage

Exploded View

Outer socket

Boot clamp (small diameter)

Boot

Boot clamp (large diameter)

Inner socket

Gear housing assembly

Disassembl ...

Other materials:

Av branch line circuit

Diagnosis Procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the av control unit for damage,

bend and loose connection (unit

side and connector side).

Is the inspection result norma ...

Locking with key

Driver’s side

The power door lock system allows you to lock or

unlock all doors at the same time.

Turning the key toward the front 1 of the vehicle

locks all doors.

Turning the key one time toward the rear 2 of the

vehicle unlocks that door. From that position,

returning the key to ...

Dtc/circuit diagnosis

Power supply and ground circuit

Audio unit

AUDIO UNIT : Diagnosis Procedure

Regarding wiring diagram information, refer to av-88, "wiring diagram".

1.Check fuse

Check that the following fuses are not blown.

Are the fuses blown?

Yes >> replace the blown fuse after repairing ...