Nissan Sentra Service Manual: Removal and installation

OIL COOLER

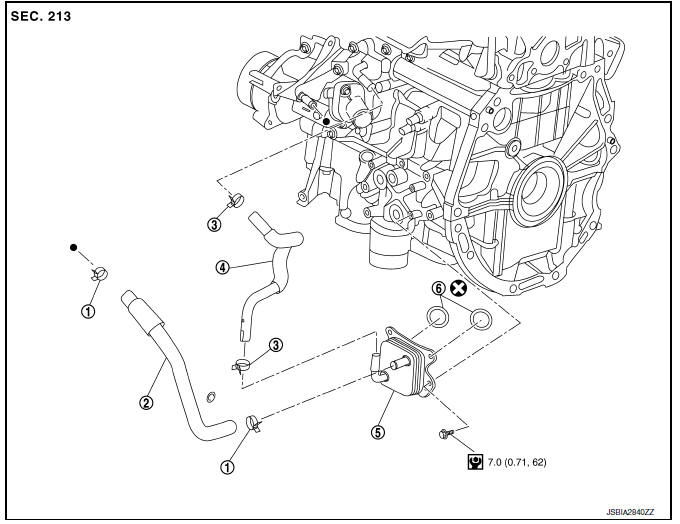

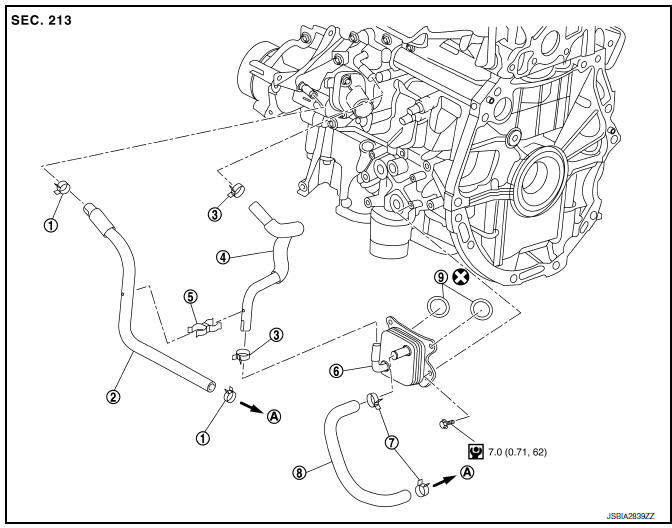

Exploded View

M/T models

- Clamp

- Water hose

- Clamp

- Water hose

- Oil cooler

- O-rings

CVT models

- Clamp

- Water hose

- Clamp

- Water hose

- Water hose clip

- Oil cooler

- Clamp

- Water hose

- O-rings

- To CVT oil warmer

Removal and Installation

REMOVAL

- Remove engine under cover. Refer to EXT-16, "Exploded View".

- Drain engine coolant. Refer to CO-12, "Changing Engine Coolant".

CAUTION:

Perform when engine is cold.

- Remove water hoses.

- Remove bolts, oil cooler and O-rings.

CAUTION:

- Be careful not to get burned when engine and engine oil may be hot.

- When removing, prepare a shop cloth to absorb any engine oil leaks or spills.

- Completely wipe off any engine oil that adheres to engine and vehicle.

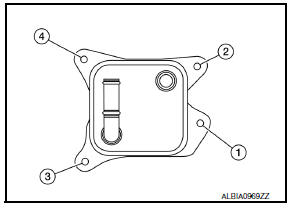

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse O-rings.

NOTE:

Tighten the oil cooler bolts in order as shown to specification.

Inspection

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary, replace oil cooler assembly.

INSPECTION AFTER INSTALLATION

- Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to LU-7, "Inspection" and CO-11, "System Inspection".

- Start the engine, and check that there are no leaks of engine oil or engine coolant.

- Stop the engine and wait for 10 minutes.

- Check the engine oil level and the engine coolant level again. Refer to LU-7, "Inspection" and CO-11, "System Inspection".

Oil filter

Oil filter

Removal and Installation

REMOVAL

Remove engine under cover. Refer to EXT-16, "Exploded View".

Drain engine oil. Refer to LU-8, "Draining".

Remove the oil filter using Too ...

Unit disassembly and assembly

Unit disassembly and assembly

OIL PUMP

O-ring

Oil pan (upper)

Oil level gauge guide

O-ring

Oil level gauge

Oil pump chain tensioner

Oil pump drive chain

Crankshaft sprocket

Oil pump sprocket

Oil pump

Dr ...

Other materials:

Rear window defogger relay

Description

Power is supplied to the rear window defogger with BCM control.

Component Function Check

1. Check rear window defogger relay power supply circuit

Turn ignition switch ON.

Check that an operation noise of rear window defogger relay (located in

IPDM E/R) can be heard when

t ...

Controls

Fan control dial

The fan control dial turns the fan on and off, and

controls fan speed.

Air flow control buttons

The air flow control buttons allow you to select

the air flow outlets.

MAX — Air flows from center and side

A/Cvents with maximum cooling.

— Air flows from center and side

v ...

Windshield-washer fluid

Windshield-washer fluid reservoir

Fill the windshield-washer fluid reservoir periodically.

To fill the windshield-washer fluid reservoir, lift

the cap off the reservoir and pour the windshieldwasher

fluid into the reservoir opening.

Add a washer solvent to the washer for better

cleanin ...