Nissan Sentra Service Manual: Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector e4

- Harness connector m2

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (open circuit)

- Disconnect the following harness connectors.

- Ipdm e/r

- Harness connectors e4 and m2

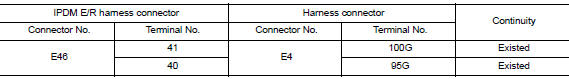

- Check the continuity between the ipdm e/r harness connector and the harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair the main line between the IPDM E/R and the harness connector E4.

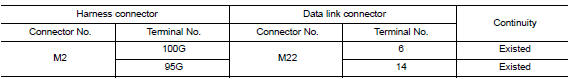

3.Check harness continuity (open circuit)

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal? Yes (present error)>>check can system type decision again.

Yes (past error)>>error was detected in the main line between the ipdm e/r and the data link connector.

No >> repair the main line between the harness connector m2 and the data link connector.

Can system (type 2)

Can system (type 2)

Dtc/circuit diagnosis ...

Ecm branch line circuit

Ecm branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ecm for damage, bend and ...

Other materials:

Vanity mirror lamp

Removal and installation

Caution:

Do not attempt to separate the vanity mirror lamp from the sun visor or

damage to the components

may occur.

Note:

The vanity mirror lamp is replaced as part of the sun visor. Refer to

int-40, "removal and installation".

Bulb or lens replacement

...

Intermittent Incident

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for

service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No

Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the conditions/env ...

Dtc/circuit diagnosis

U1000 can comm circuit

Description

Refer to lan-7, "can communication system : system description".

DTC Logic

Dtc detection logic

Note:

U1000 can be set if a module harness was disconnected and reconnected,

perhaps during a repair. Confirm

that there are actual can diagnostic sym ...