Nissan Sentra Service Manual: Removal and installation

A/C ASSEMBLY SWITCH

Removal and Installation

Removal

- Remove the cvt shift selector finisher (cvt: re0f11a). Refer to tm-253, "removal and installation".

- Remove the MT shift selector finisher (6MT: RS6F94R). Refer to TM-22, "Exploded View".

- Remove the front air control screws.

- Release the front air control metal clips using a suitable tool.

- Disconnect the harness connectors from the A/C assembly switch and remove.

Installation

Installation is in the reverse order of removal.

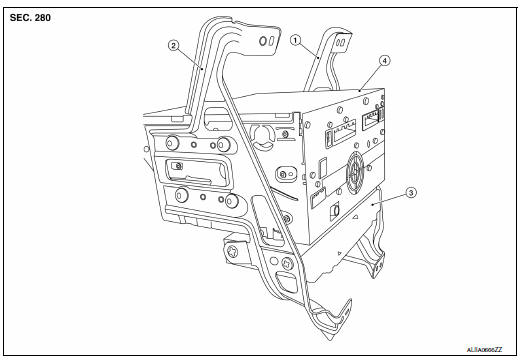

A/C AUTO AMP

Exploded View

- AV control unit bracket (LH)

- AV control unit bracket (RH)

- A/C auto amp.

- AV control unit

Removal and Installation

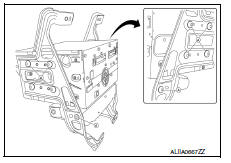

REMOVAL

- Remove the AV control unit. Refer to AV-406, "Removal and Installation".

- Remove the AV control unit bracket screws (A).

- Remove the A/C auto amp.

INSTALLATION

Installation is in the reverse order of removal.

INTAKE SENSOR

Removal and Installation

The intake sensor is serviced as an assembly with the heating and cooling unit assembly. Refer to HA-43, "HEATING AND COOLING UNIT ASSEMBLY : Removal and Installation".

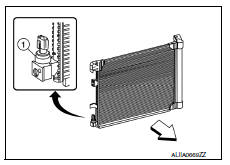

Refrigerant pressure sensor

Removal and Installation

REMOVAL

- Discharge the refrigerant. Refer to HA-23, "Recycle Refrigerant".

- Remove the core support upper. Refer to HA-39, "Exploded View".

- Disconnect the harness connector from the refrigerant pressure sensor.

- Remove the refrigerant pressure sensor (1).

CAUTION:

Cap or wrap the opening of the refrigerant pressure sensor with suitable material such as vinyl tape to avoid the entry of air.

Installation

Installation is in the reverse order of removal.

Caution:

- Do not reuse o-ring.

- Apply a/c oil to the o-ring of the refrigerant pressure sensor for installation.

- After charging refrigerant, check for leaks. Refer to ha-21, "leak test".

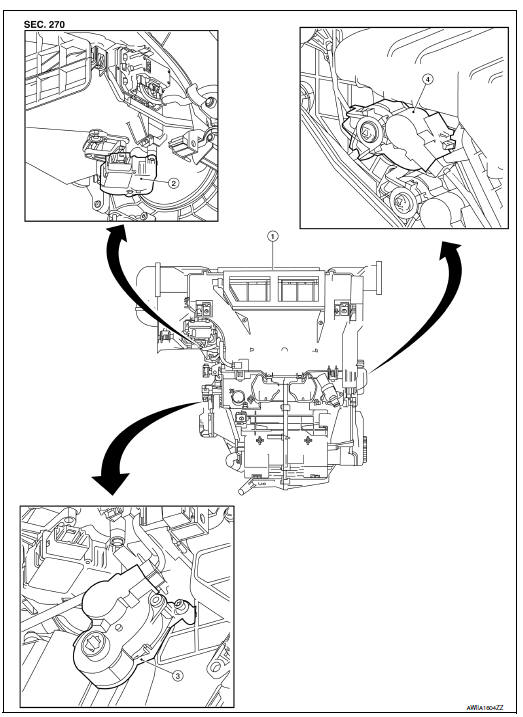

Door motor

Exploded View

- Heating and cooling unit assembly

- Intake door motor

- Mode door motor

- Air mix door motor

INTAKE DOOR MOTOR

INTAKE DOOR MOTOR : Removal and Installation

Removal

- Remove the heating and cooling unit assembly. Refer to ha-43, "heating and cooling unit assembly : removal and installation".

- Disconnect the harness connector from the intake door motor.

- Remove the intake door motor screws and the intake door motor.

Installation

Installation is in the reverse order of removal.

MODE DOOR MOTOR

MODE DOOR MOTOR : Removal and Installation

Removal

- Remove the front floor duct LH. Refer to HA-42, "Exploded View".

- Disconnect the harness connector from the mode door motor.

- Remove the mode door motor screws and the mode door motor.

Installation

Installation is in the reverse order of removal.

AIR MIX DOOR MOTOR

AIR MIX DOOR MOTOR : Removal and Installation

Removal

- Remove the glove box assembly. Refer to IP-22, "Removal and Installation".

- Disconnect the harness connector from the air mix door motor

- Remove the air mix door motor screws and the air mix door motor.

Installation

Installation is in the reverse order of removal.

BLOWER MOTOR RESISTOR

Removal and Installation

Removal

- Remove the instrument lower panel LH. Refer to IP-21, "Removal and Installation".

- Disconnect the harness connector from the blower motor resistor.

- Release the pawls using a suitable tool and remove the blower motor resistor.

Installation

Installation is in the reverse order of removal.

Symptom diagnosis

Symptom diagnosis

HEATER AND AIR CONDITIONING SYSTEM

CONTROL SYMPTOMS

Symptom Table

INSUFFICIENT COOLING

Component Function Check

Symptom: insufficient cooling

Inspection flow

1. Confirm symptom by performin ...

Body interior

Body interior

...

Other materials:

Starting system (without intelligent key)

Wiring Diagram

...

Preparation

Special Service Tool

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tool

Clip list

Descriptions for Clips

Replace any clips which are damaged during removal or installation.

...

Types of tires

WARNING

When changing or replacing tires, be

sure all four tires are of the same type

(i.e., Summer, All Season or Snow) and

construction. A NISSAN dealer may be

able to help you with information about

tire type, size, speed rating and

availability.

Replacement ...