Nissan Sentra Service Manual: P2014, P2016, P2017, P2018 Intake manifold runner control valve position sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2014, P2016, P2017 or P2018 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to EC-353, "DTC Logic".

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P2014 | IN/MANIFOLD RUNNER POS SEN B1 (Intake manifold runner position sensor/ switch circuit bank 1) | An excessively low voltage from the sensor is sent to ECM. |

|

| P2016 | IN/MANIFOLD RUNNER POS SEN B1 (Intake manifold runner position sensor/ switch circuit low bank 1) | ||

| P2017 | IN/MANIFOLD RUNNER POS SEN B1 (Intake manifold runner position sensor/ switch circuit high bank 1) | An excessively high voltage from the sensor is sent to ECM. | |

| P2018 | IN/MANIFOLD RUNNER POS SEN B1 (Intake manifold runner position sensor/ switch circuit intermittent bank 1) |

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for 10 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-416, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

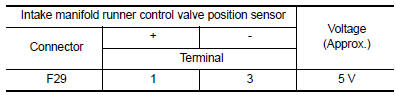

1.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect intake valve manifold runner control valve position sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between intake valve manifold runner control valve position sensor harness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 2.

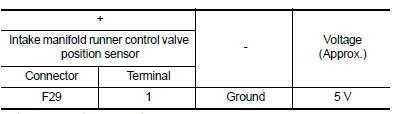

2.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR POWER SUPPLY CIRCUIT

Check the voltage between intake valve manifold runner control valve position sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Check sensor power supply 2 circuit. Refer to EC-444, "Diagnosis Procedure".

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

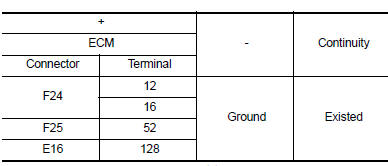

4.CHECK ECM GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between ECM harness connector and ground.

- Also check harness for short to power.

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

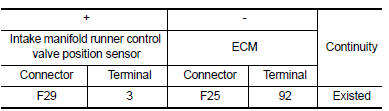

5.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

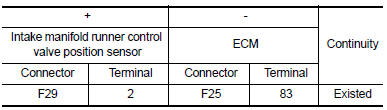

- Check the continuity between intake manifold runner control valve position sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK INTAKE MANIFOLD RUNNER CONTROL VALVE POSITION SENSOR INPUT SIGNAL CIRCUIT

- Check the continuity between intake manifold runner control valve position sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

7.CHECK INTERMITTENT INCIDENT

Perform GI-39, "Intermittent Incident".

Is the inspection result normal? YES >> Replace intake manifold assembly. Refer to EM-27, "Exploded View".

NO >> Repair or replace error-detected parts.

P2004 Intake manifold runner control valve

P2004 Intake manifold runner control valve

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P2004

TUMBLE CONT/V

(Intake manifold r ...

P2096, P2097 A/F Sensor 1

P2096, P2097 A/F Sensor 1

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible Cause

P2096

POST CAT FUEL TRIM SYS B1

(Post ...

Other materials:

Rear door glass

Removal and Installation

REMOVAL

NOTE:

LH rear door panel shown; RH similar.

Remove the rear door finisher. Refer to INT-19, "Removal and

Installation".

Remove the vapor barrier.

CAUTION:

Use care to not damage or tear vapor barrier during removal.

Remove the rear door ...

Chassis and body maintenance

In-cabin microfilter

In-cabin microfilter : removal and installation

REMOVAL

Remove the in-cabin microfilter cover.

CAUTION:

Before removing the in-cabin microfilter cover, let the vehicle rest

for at least 30 minutes.

Release the filter cover tab (A), then pull the bottom of the in- ...

Changing engine oil filter

Park the vehicle on a level surface and apply

the parking brake.

Turn the engine off.

Place a large drain pan under the oil filter C .

Loosen the oil filter with an oil filter wrench

by turning it counterclockwise. Then remove

the oil filter by turning it by hand.

CAUTION

Be c ...