Nissan Sentra Service Manual: P1550 Battery current sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P1550 | BAT CURRENT SENSOR (Battery current sensor) | The output voltage of the battery current sensor remains within the specified range while engine is running. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and wait at least 10 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-374, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

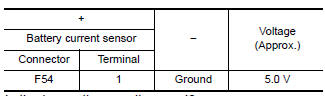

1.CHECK BATTERY CURRENT SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect battery current sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between battery current sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Check sensor power supply 2 circuit. Refer to EC-444, "Diagnosis Procedure".

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

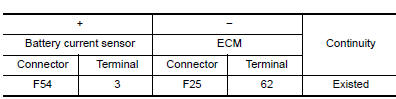

3.CHECK BATTERY CURRENT SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between battery current sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

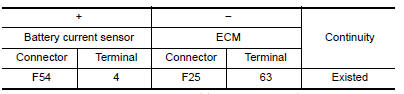

4.CHECK BATTERY CURRENT SENSOR INPUT SIGNAL CIRCUIT

- Check the continuity between battery current sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts

5.CHECK BATTERY CURRENT SENSOR

Check the battery current sensor. Refer to EC-375, "Component Inspection (Battery Current Sensor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace battery current sensor. Refer to PG-53, "Removal and Installation".

Component Inspection (Battery Current Sensor)

1.CHECK BATTERY CURRENT SENSOR

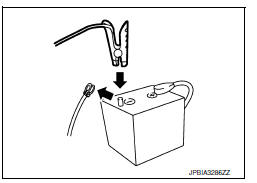

- Turn ignition switch OFF.

- Reconnect harness connectors disconnected.

- Disconnect battery negative cable.

- Install jumper cable between battery negative terminal and body ground.

- Turn ignition switch ON.

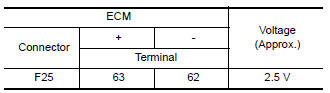

- Check the voltage between ECM harness connector terminals.

Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to PG-4, "How to Handle Battery".

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace battery current sensor. Refer to PG-53, "Removal and Installation".

P1226 TP Sensor

P1226 TP Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1226

CTP LEARNING-B1

(CTP LEARNING-B1 ...

P1551, P1552 Battery current sensor

P1551, P1552 Battery current sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1551

BAT CURRENT SENSOR

(Battery curr ...

Other materials:

Charging system

System Diagram

System Description

The generator provides DC voltage to operate the vehicle's electrical system

and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Component Description

...

Component parts

Meter system

METER SYSTEM : Component Parts Location

ABS actuator and electric unit (control

unit)

Combination meter

CVT shift selector (with CVT)

(O/D OFF switch)

Air bag diagnosis sensor unit

(view with center console assembly removed)

Parking brake switch

(view with ...

Wiring diagram

BCM

Wiring diagram

...