Nissan Sentra Service Manual: P0746 Pressure control solenoid A

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P0746 | PRESSURE CONTROL SOLENOID A (Pressure Control Solenoid A Performance/Stuck Off) | The detecting condition A or detection condition

B is detected twice or more (1 second or

more later after detection of the first) in the

same DC under the following diagnosis conditions: Diagnosis conditions

Detection condition A

Detection condition B

|

|

NOTE:

DC stands for “DRIVING CYCLE” and indicates a series of driving cycle of “Ignition switch OFF → ON → driving → OFF”.

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine.

- Drive the vehicle.

- Maintain the following conditions for 10 seconds or more.

Selector lever : “D” position

Accelerator pedal position : 0.1/8 or more

Vehicle speed : 40 km/h (25 MPH) or more

- Stop the vehicle.

- Check the first trip DTC.

Is “P0746”detected? YES >> Go to TM-191, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK LINE PRESSURE SOLENOID VALVE

- Turn ignition switch OFF.

- Disconnect CVT unit connector.

- Check line pressure solenoid valve. Refer to TM-191, "Component Inspection"

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK LINE PRESSURE

Perform line pressure test. Refer to TM-149, "Work Procedure".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace the malfunction items.

Component Inspection

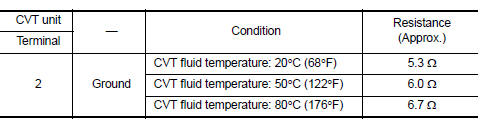

1.CHECK LINE PRESSURE SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> INSPECTION END

NO >> There is a malfunction of line pressure solenoid valve. Replace transaxle assembly. Refer to TM- 283, "Removal and Installation".

P0744 Torque converter

P0744 Torque converter

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0744

TORQUE CONVERTER

(Torque converter ...

P0846 Transmission fluid pressure SEN/SW B

P0846 Transmission fluid pressure SEN/SW B

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0846

TRANSMISSION FLUID

PRESSURE SEN/SW ...

Other materials:

C1115 ABS Sensor [abnormal signal]

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1115

ABS SENSOR

[ABNORMAL SIGNAL]

When difference in wheel speed between any wheel

and others is detected while the vehicle is driven, because

of installation of t ...

Break-in schedule

CAUTION

During the first 1,200 miles (2,000 km),

follow these recommendations to obtain

maximum engine performance and ensure

the future reliability and economy of your

new vehicle. Failure to follow these recommendations

may result in shortened

engine life and reduced engine

performance.

A ...

Wiring diagram

Door mirror

Wiring diagram

Inside mirror

Wiring Diagram

...