Nissan Sentra Service Manual: P0720 Output speed sensor

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P0720 | OUTPUT SPEED SENSOR (Output Speed Sensor Circuit) | The output speed sensor value is less than

150 rpm continuously for 5 seconds or more

under the following diagnosis conditions: Diagnosis conditions

|

|

| The output speed sensor value is 90 rpm or

less continuously for 500 msec or more under

the following diagnosis conditions: Diagnosis conditions

|

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another –≤–Ç—öDTC CONFIRMATION PROCEDURE–≤–Ç—ú occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

- Start the engine.

- Drive the vehicle.

- Maintain the following conditions for 10 seconds or more.

Selector lever : –≤–Ç—öD–≤–Ç—ú position

Vehicle speed : 55 km/h (34 MPH) or more

- Stop the vehicle.

- Check the first trip DTC.

Is –≤–Ç—öP0720–≤–Ç—ú detected? YES >> Go to TM-181, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

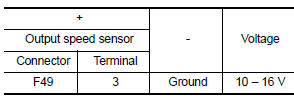

1.CHECK OUTPUT SPEED SENSOR POWER CIRCUIT

- Turn ignition switch OFF.

- Disconnect output speed sensor connector.

- Turn ignition switch ON.

- Check voltage between output speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 2.

NO >> GO TO 6.

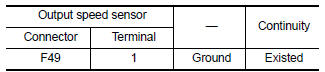

2.CHECK OUTPUT SPEED SENSOR GROUND CIRCUIT

Check the continuity between output speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 3.

NO >> Repair or replace malfunctioning parts.

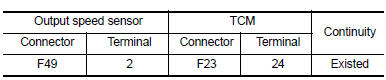

3.CHECK CIRCUIT BETWEEN OUTPUT SPEED SENSOR AND TCM (PART 1)

- Turn ignition switch OFF.

- Disconnect TCM connector

- Check continuity between output speed sensor harness connector terminal and TCM harness connector terminal.

Is the check result normal? YES >> GO TO 4.

NO >> Repair or replace malfunctioning parts.

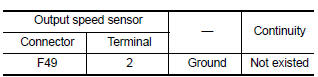

4.CHECK CIRCUIT BETWEEN OUTPUT SPEED SENSOR AND TCM (PART 2)

Check continuity between output speed sensor harness connector terminal and ground.

Is the check result normal? YES >> GO TO 5.

NO >> Repair or replace malfunctioning parts.

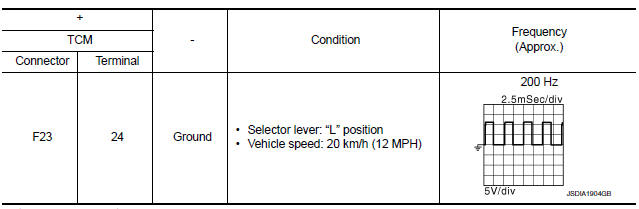

5.Check tcm input signals

- Connect all of disconnected connectors.

- Lift the vehicle.

- Start the engine.

- Check frequency of output speed sensor.

Is the check result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace output speed sensor. Refer to TM-270, "Exploded View".

6.DETECT MALFUNCTIONING ITEMS

Check the following items:

- Harness open circuit or short circuit between ignition switch and IPDM E/R. Refer to PG-20, "Wiring Diagram — Ignition Power Supply —".

- Harness open circuit or short circuit between IPDM E/R and output speed sensor.

- 10A fuse (No.45, IPDM E/R). Refer to PG-49, "IPDM E/R Terminal Arrangement".

- IPDM E/R

Is the check result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

P0715 Input speed sensor A

P0715 Input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0715

INPUT SPEED SENSOR A

...

P0740 Torque converter

P0740 Torque converter

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0740

TORQUE CONVERTER

(Torque Converter ...

Other materials:

Fuel injector and fuel tube

Exploded View

Bracket

Fuel tube bracket

Fuel feed tube

Quick connector cap

Fuel tube

O-ring (black)

Fuel injector

O-ring (green)

Injector clip

CAUTION:

Do not remove or disassemble parts unless instructed.

Removal and Installation

WARNING:

Put a –≤–Ç—öCAUTION: FLAM ...

Service Notice and Precautions for EPS System

Check the following item when performing the trouble

diagnosis.

Check any possible causes by interviewing the symptom and

it′s condition from the customer if any malfunction,

such as EPS warning lamp is turned ON, occurs.

Check if air pressure and size of tires are proper, t ...

Precaution for supplemental restraint system (srs) "air bag" and "seat belt

pre-tensioner"

The Supplemental Restraint System such as –≤–Ç—öAIR BAG–≤–Ç—ú and –≤–Ç—öSEAT BELT PRE-TENSIONER–≤–Ç—ú,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...