Nissan Sentra Service Manual: P0453 EVAP Control system pressure sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0453 | EVAP SYS PRES SEN (Evaporative emission system pressure sensor/switch high) | An excessively high voltage from the sensor is sent to ECM. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Always perform test at a temperature of 5В°C (41В°F) or more.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

With CONSULT

With CONSULT

- Start engine and warm it up to normal operating temperature.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Select “DATA MONITOR” mode of “ENGINE” using CONSULT.

- Make sure that “FUEL T/TMP SE” indication is more than 0°C (32°F).

- Start engine and wait at least 20 seconds.

- Check 1st trip DTC.

With GST

With GST

- Start engine and warm it up to normal operating temperature.

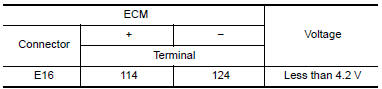

- Set voltmeter probes to ECM harness connector terminals as per the following.

- Make sure that the voltage is less than 4.2 V.

- Turn ignition switch OFF and wait at least 10 seconds.

- Start engine and wait at least 20 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-316, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR FOR WATER

- Turn ignition switch OFF.

- Disconnect EVAP control system pressure sensor harness connector.

- Check sensor harness connector for water.

Water should not exist.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace harness connector.

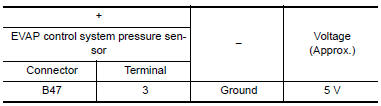

2.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY

- Turn ignition switch ON.

- Check the voltage between EVAP control system pressure sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

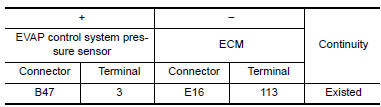

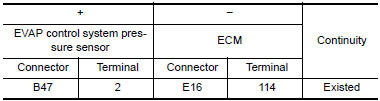

3.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP control system pressure sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts

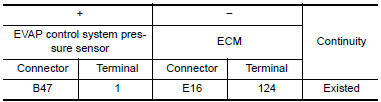

4.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector

- Check the continuity between EVAP control system pressure sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR SIGNAL CIRCUIT

- Check the continuity between EVAP control system pressure sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK RUBBER TUBE

- Disconnect rubber tube connected to EVAP canister vent control valve.

- Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 7.

NO >> Clean the rubber tube using an air blower, repair or replace rubber tube.

7.CHECK EVAP CANISTER VENT CONTROL VALVE

Refer to EC-303, "Component Inspection".

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP canister vent control valve. Refer to FL-15, "Removal and Installation".

8.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-319, "Component Inspection".

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace EVAP control system pressure sensor. Refer to FL-15, "Removal and Installation".

9.CHECK IF EVAP CANISTER IS SATURATED WITH WATER

- Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor attached.

- Check if water will drain from the EVAP canister.

Does water drain from EVAP canister? YES >> GO TO 10.

NO >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

10.CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor attached.

The weight should be less than 1.9 kg (4.2 lb).

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> GO TO 11.

11.DETECT MALFUNCTIONING PART

Check the following.

- EVAP canister for damage

- EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. Refer to FL-15, "Removal and Installation".

Component Inspection

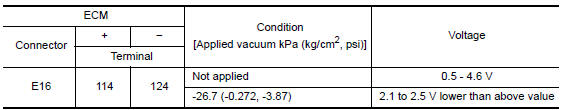

1.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

- Turn ignition switch OFF.

- Remove EVAP control system pressure sensor with its harness connector

connected from EVAP canister.

Always replace O-ring with a new one.

- Install a vacuum pump to EVAP control system pressure sensor.

- Turn ignition switch ON and check output voltage between ECM harness connector and ground under the following conditions.

CAUTION:

- Always calibrate the vacuum pump gauge when using it.

- Do not apply below -93.3 kPa (-0.952 kg/cm2, -13.53 psi) or pressure over 101.3 kPa (1.033 kg/ cm2, 14.69 psi).

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVAP control system pressure sensor. Refer to FL-15, "Removal and Installation".

P0452 EVAP Control system pressure sensor

P0452 EVAP Control system pressure sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0452

EVAP SYS PRES SEN

(Evaporative e ...

P0456 EVAP Control system

P0456 EVAP Control system

DTC Logic

DTC DETECTION LOGIC

This diagnosis detects leaks in the EVAP line between fuel tank and EVAP

canister purge volume control solenoid

valve, using the negative pressure caused by decrease ...

Other materials:

P0340 CMP Sensor (PHASE)

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0340

CMP SEN/CIRC-B1

(Camshaft position sensor

“A” circuit bank 1)

The cylinder No. signal is not sent to ECM fo ...

Periodic maintenance

ENGINE COOLANT

System Inspection

WARNING:

Do not remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure

engine coolant escaping from the radiator.

Wrap a thick cloth around the cap. Slowly push down and turn it

a quarter turn to allow built-up pr ...

Precaution for Work

When removing or disassembling each component, be careful not to damage

or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar

tool, be sure to wrap the component

with a ...