Nissan Sentra Service Manual: P0182, P0183 FTT Sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0182 | FTT SEN/CIRCUIT (Fuel temperature sensor ″A″ circuit low) | An excessively low voltage from the sensor is sent to ECM. |

|

| P0183 | FTT SEN/CIRCUIT (Fuel temperature sensor ″A″ circuit high) | An excessively high voltage from the sensor is sent to ECM. |

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-258, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK DTC WITH COMBINATION METER

Refer to MWI-17, "CONSULT Function (METER/M&A)".

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to MWI-58, "Diagnosis Procedure".

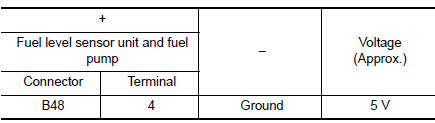

2.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector.

- Turn ignition switch ON.

- Check the voltage between fuel level sensor unit and fuel pump harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

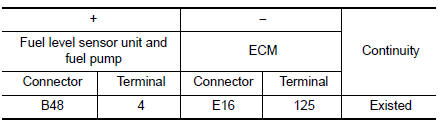

3.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between fuel level sensor unit and fuel pump harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

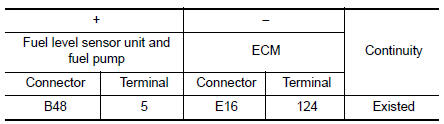

4.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM connector.

- Check the continuity between fuel level sensor unit and fuel pump harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

Check the FTT sensor. Refer to EC-259, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace “fuel level sensor unit and fuel pump”. Refer to FL-6, "Removal and Installation".

Component Inspection

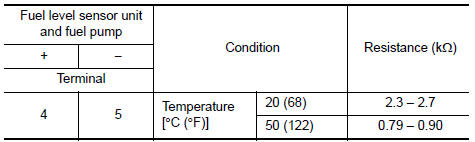

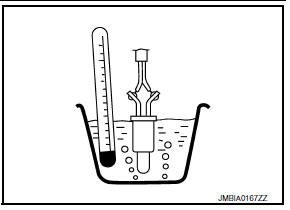

1.CHECK FUEL TANK TEMPERATURE (FTT) SENSOR

- Turn ignition switch OFF.

- Disconnect fuel level sensor unit and fuel pump harness connector.

- Remove fuel level sensor unit. Refer to FL-6, "Removal and Installation".

- Check resistance between fuel level sensor unit and fuel pump terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace fuel level sensor unit and fuel pump. Refer to FL-6, "Removal and Installation".

P0181 FTT Sensor

P0181 FTT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0181

FTT SENSOR

(Fuel temperature sen ...

P0196 EOT Sensor

P0196 EOT Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0196 is displayed with DTC P0197 or P0198, first perform the

trouble diagnosis for DTC P0197 or

P0198. Refer to EC-264, "DTC Logic".

...

Other materials:

Abs branch line circuit

Diagnosis procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ABS actuator and electric unit

(control unit) for damage, bend

and loose connection (unit side and connector side).

...

P0122, P0123 TP Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the

trouble diagnosis for DTC P0643.

Refer to EC-353, "DTC Logic".

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible caus ...

Voice commands

You can use voice commands to operate various

Bluetooth® Hands-Free Phone System features

using the NISSAN Voice Recognition system. For

more details, see “NISSAN Voice Recognition

System” in this section.

Voice Prompt Interrupt

While using the voice recognition system, the

system voice ...