Nissan Sentra Service Manual: P0117, P0118 ECT Sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0117 | ECT SEN/CIRC (Engine coolant temperature sensor 1 circuit low) | An excessively low voltage from the engine coolant temperature sensor is sent to ECM. |

|

| P0118 | ECT SEN/CIRC (Engine coolant temperature sensor 1 circuit high) | An excessively high voltage from the engine coolant temperature sensor is sent to ECM. |

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check DTC.

Is DTC detected? YES >> Proceed to EC-198, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

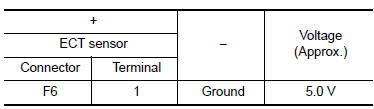

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect engine coolant temperature (ECT) sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between ECT sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

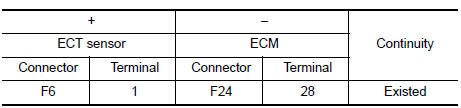

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between ECT sensor harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

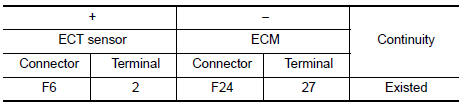

3.CHECK ENGINE COOLANT TEMPERATURE SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between ECT sensor harness connector and ECM harness connector.

- Also check harness for short to ground to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check the engine coolant temperature sensor. Refer to EC-199, "Component Inspection (ECT Sensor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "Exploded View".

Component Inspection (ECT Sensor)

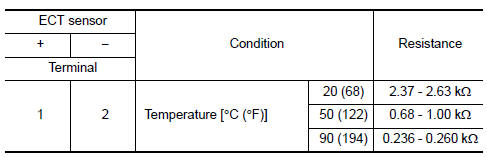

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

- Turn ignition switch OFF.

- Disconnect engine coolant temperature sensor harness connector.

- Remove engine coolant temperature sensor.

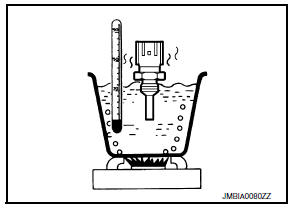

- Check resistance between engine coolant temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace engine coolant temperature sensor. Refer to CO-24, "Exploded View".

P0116 ECT Sensor

P0116 ECT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0116

ECT SEN/CIRC

(Engine coolant tem ...

P0122, P0123 TP Sensor

P0122, P0123 TP Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the

trouble diagnosis for DTC P0643.

Refer to EC-353, "DTC Logic".

DTC No ...

Other materials:

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

NOTE:

“DTC” includes DTC at the 1st trip.

1.OBTAIN INFORMATION ABOUT SYMPTOM

Refer to TM-140, "Diagnostic Work Sheet" and interview the customer to obtain

the malfunction information

(conditions and environment when the malfunctio ...

Preparation

Special Service Tools

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tools

Clip list

Descriptions for Clips

Replace any clips which are damaged during removal or installation.

...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...