Nissan Sentra Service Manual: Flywheel

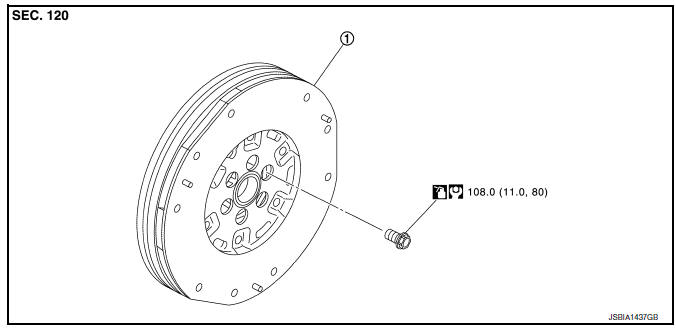

Exploded View

- Flywheel

Removal and Installation

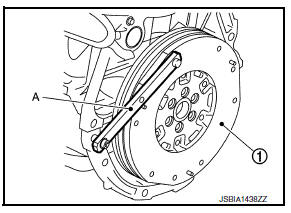

REMOVAL

- Remove the engine and the transaxle assembly from the vehicle, and separate the transaxle from the engine. Refer to TM-28, "Exploded View".

- Remove flywheel.

- Secure flywheel (1) using Tool (A), and remove bolts using suitable tool.

Tool number : KV11105210 (J-44716)

CAUTION:

- Do not disassemble flywheel.

- Do not place flywheel with signal plate facing down.

- When handling signal plate, take care not to damage or scratch.

- Handle signal plate, do so in a manner that prevents it from becoming magnetized.

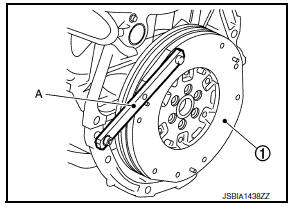

INSTALLATION

- Install flywheel.

- Secure flywheel (1) using Tool (A), and install bolts.

Tool number : KV11105210 (J-44716)

CAUTION:

Be careful not to damage or scratch the contact surface of flywheel.

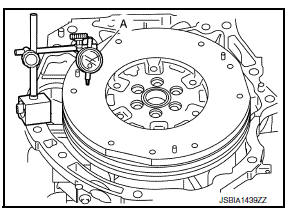

Inspection

FLYWHEEL DEFLECTION

- Measure the deflection of flywheel contact surface to torque with a dial indicator (A).

- Measure the deflection at 210 mm (8.27 in) diameter.

Limit : 0.45 mm (0.0177 in) or less.

- If measured value is out of the standard, replace flywheel.

- If a trace of burn or discoloration is found on the surface, repair it with sandpaper.

MOVEMENT AMOUNT OF FLYWHEEL

CAUTION:

Do not disassemble double mass flywheel.

Movement Amount of Thrust (Fore-and-Aft) Direction

- Measure the movement amount of thrust (fore-and-aft) direction when 100 N (10.2 kg, 22 lb) force is added at the portion of 125 mm (4.92 in) radius from the center of flywheel.

Standard : 1.8 mm (0.071 in) or less

- If measured value is out of the standard, replace flywheel

Movement Amount in Radial (Rotation) Direction

Check the movement amount of radial (rotation) direction with the following procedure:

- Install clutch cover bolt (1) to clutch cover hole, and place a torque wrench (A) on the extended line of the flywheel (2) center line.

- Tighten bolt at a force of 9.8 NВ·m (1.0 kg-m, 87 in-lb) to keep it from loosening.

- Put a mating mark on circumferences of the two flywheel masses without applying any load (Measurement standard points).

- Apply a force of 9.8 NВ·m (1.0 kg-m, 87 in-lb) in each direction, and mark the movement amount on the mass on the transaxle side.

- Measure the dimensions of movement amounts (A) and (B) on circumference of the flywheel on the transaxle side.

Limit : 33.2 mm (1.307 in) or less.

- If measured value is out of the standard, replace flywheel.

Drive plate

Drive plate

Exploded View

Pilot converter

Drive plate

Reinforcement plate

Chamfered

Removal and Installation

REMOVAL

Remove the engine and the transaxle assembly from the vehicle, and

...

Other materials:

S terminal circuit

Description

The output voltage of the generator is controlled by the IC regulator at

terminal “S” detecting the input voltage

from battery.

The “S” terminal circuit detects the battery voltage to adjust the generator

output voltage with the IC voltage

regulator.

Diagn ...

Operating range

The Intelligent Key functions can only be used

when the Intelligent Key is within the specified

operating range from the request switch 1.

When the Intelligent Key battery is discharged or

strong radio waves are present near the operating

location, the Intelligent Key operating range

becom ...

Nissan Customer care program

NISSAN CARES . . .

Both NISSAN and your NISSAN dealer are dedicated to serving all your

automotive needs. Your satisfaction with your vehicle and your NISSAN dealer are

our primary concerns. Your NISSAN dealer is always available to assist you with

all your automobile sales and service needs.

...