Nissan Sentra Service Manual: Exhaust valve timing control

EXHAUST VALVE TIMING CONTROL : System Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

| Sensor | Input signal to ECM | ECM function | Actuator | |

| Crankshaft position sensor (POS) | Engine speed and piston position | Exhaust valve timing control | Exhaust valve timing control solenoid valve | |

| Camshaft position sensor (PHASE) | ||||

| Engine oil temperature sensor | Engine oil temperature | |||

| Exhaust valve timing control position sensor | Exhaust valve timing signal | |||

| Combination meter | CAN communication | Vehicle speed signal | ||

SYSTEM DESCRIPTION

This engine is equipped with an exhaust valve timing controller (integral with cam sprocket) which continuously adjusts the phase of intake valve according to driving conditions, improves both low/mid range engine torque and high-speed range engine output, and brings about low emission and low fuel consumption.

The exhaust valve timing control system continuously controls cam phases in constant exhaust valve operating angle conditions and adjusts an operating oil pressure to the exhaust valve timing controller via the control solenoid valve.

ECM receives exhaust valve timing control position signal, crankshaft position signal, engine speed signal, engine oil temperature signal, and engine coolant temperature signal. And the ECM outputs ON/OFF pulse duty signals to the exhaust valve timing control solenoid valve depending on driving status.

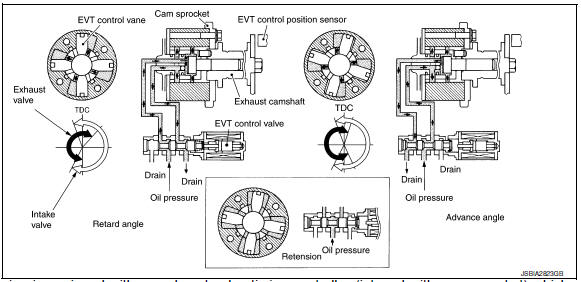

Exhaust Valve Timing Controller Operation List

| Exhaust valve timing solenoid valve condition | Exhaust valve timing controller operation |

| Engine OFF | When starting the engine, the controller vane and sprocket are fixed in full retard position by the reaction force of return spring, improving the starting performance of the engine. |

| Active (Retard angle) | When the energization rate to the control solenoid valve is

increased, the oil pressure from the oil

pump is conveyed to the retard angle chamber of the controller. And

advance angle chamber oil is

drained. Accordingly, the controller vane rotates leftward and the phase

of camshaft becomes retard

angle.

This condition brings about the greater overlap with the exhaust valve, enabling the exhaust gas cleaning by the internal EGR effect and the fuel consumption improvement by the reduction in pumping loss. |

| Neutral (Maintained) | When it is the target valve timing, the energization rate to the control solenoid valve is adjusted to the intermediate state. The solenoid valve is positioned at the neutral position and the oil path is interrupted to maintain the cam shaft phase. |

| Return (Advance angle) | When the energization rate to the control solenoid valve is

decreased, the oil pressure from the oil

pump is conveyed to the advance angle chamber of the controller. And

retard angle chamber oil is

drained.

Accordingly, the controller vane rotates rightward and the phase of camshaft becomes advance angle. |

EXHAUST VALVE TIMING CONTROL FEEDBACK CONTROL

Cam Position Detection

The exhaust valve control position sensor mounted at the rear of the cylinder head detects a cam position, by using the groove on the plate located at the rear of the intake camshaft.

Feedback Control

The exhaust valve control position sensor feeds back an actual cam position signal to ECM. Based on the signal, ECM controls the exhaust valve timing control solenoid valve to satisfy the optimum target valve opening/ closing timing according to a driving condition.

Intake valve timing control

Intake valve timing control

INTAKE VALVE TIMING CONTROL : System Description

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

Sensor

Input signal to ECM

ECM function

Actuator

Crankshaft position sensor (P ...

Intake manifold runner control

Intake manifold runner control

INTAKE MANIFOLD RUNNER CONTROL : System

Description

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

Intake manifold runner control valve has a valve portion in the intake

passage of each cylinder.

Whil ...

Other materials:

Symptom diagnosis

Squeak and rattle trouble diagnoses

Work Flow

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist

when the noise occurs. Use the Diagnostic

Worksheet during the interview to document the facts and conditions when the

noise occurs and any

custome ...

Brake warning lamp

Component Function Check

1.CHECK BRAKE WARNING LAMP FUNCTION (1)

Check that brake warning lamp in combination meter turns ON for

approximately 2 seconds after ignition

switch is turned ON.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Proceed to diagnosis procedure. ...

Trunk lid

Trunk lid assembly

Trunk lid assembly : exploded view

Trunk lid hinge LH/RH

Torsion bar LH/RH

Torsion bar clips

Trunk lid finisher (if equipped)

Emergency release handle

Emergency release handle clip

Emergency release handle cable

Trunk lid lock

Trunk lid bumpers

License lam ...