Nissan Sentra Service Manual: Dlc branch line circuit

Diagnosis Procedure

1.Check connector

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal

- Check the terminals and connectors of the data link connector for damage, bend and loose connection (connector side and harness side).

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

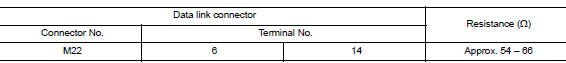

2.Check harness for open circuit

Check the resistance between the data link connector terminals.

Is the measurement value within the specification? YES (Present error)>>Check CAN system type decision again.

YES (Past error)>>Error was detected in the data link connector branch line circuit.

NO >> Repair the data link connector branch line.

A-bag branch line circuit

A-bag branch line circuit

Diagnosis procedure

Warning:

Always observe the following items for preventing accidental

activation.

Before servicing, turn ignition switch off, disconnect battery

negative terminal, and w ...

Eps branch line circuit

Eps branch line circuit

Diagnosis Procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the eps control unit for dam ...

Other materials:

CVT Fluid filter

Exploded View

Transaxle assembly

CVT fluid filter

Fluid filter cover

CVT fluid

Removal and Installation

REMOVAL

Remove neighboring parts of CVT fluid filter.

Remove fluid filter cover mounting bolt (A).

Remove fluid filter cover (1) from transaxle by rotating leftw ...

Body side trim

Exploded View

Rear body side welt

Front body side welt

Tether clip

Front pillar finisher

Metal clip

Dash clip

Dash side finisher

Harness protector

Front kicking plate inner

Center pillar lower finisher

Rear kicking plate inner

Cap

Center pillar upper finisher

Rear p ...

Brake fluid

Drain and Refill

CAUTION:

Do not spill or splash brake fluid on painted surfaces. Brake

fluid may damage paint. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Prior to repair, turn the ignition switch OFF, disconnect the ABS

actuator and electric uni ...