Nissan Sentra Service Manual: Compressor

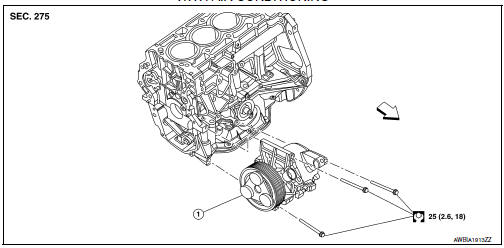

Exploded view

With air conditioning

- Compressor

Front

Front

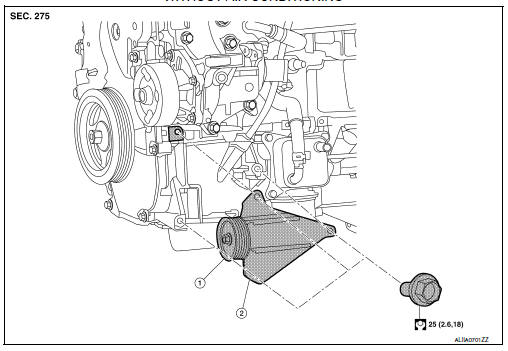

Without air conditioning

- A/c idler pulley

- A/c idler pulley bracket

Compressor

Compressor : removal and installation

REMOVAL

- Discharge the refrigerant. Refer to ha-23, "recycle refrigerant".

- Remove the front under cover. Refer to ext-31, "engine under cover : removal and installation".

- Partially remove the front fender protector (rh). Refer to ext-28, "fender protector : removal and installation - front fender protector".

- Remove the drive belt from the compressor. Refer to EM-15, "Removal and Installation".

Note:

Complete removal of the drive belt is not necessary.

- Remove the bolt that retains the high-pressure flexible hose to the compressor, then disconnect the highpressure flexible hose from the compressor.

Caution:

Cap or wrap the joint of the a/c pipes with suitable material such as vinyl tape to avoid the entry of air.

- Remove the bolt that retains the low-pressure flexible hose to the compressor, then disconnect the lowpressure flexible hose from the compressor.

- Disconnect the harness connector from the compressor.

- Remove the compressor bolts and the compressor.

Installation

Installation is in the reverse order of removal.

Caution:

- Do not reuse the o-rings.

- Apply a/c compressor oil to the new o-rings for installation.

- After charging the a/c refrigerant, check for leaks. Refer to ha-21, "leak test".

- Tighten the compressor bolts to the specified torque. Refer to HA-30, "Exploded View".

Magnet clutch

Magnet clutch : removal and installation

Removal

- Remove the compressor. Refer to ha-31, "compressor : removal and installation".

- Remove the center bolt by holding the clutch disc steady using the clutch disc holding tool.

Tool number : (j-44614)

- Remove the clutch disc and shim(s).

Caution:

Retain shim(s) for installation.

- Remove the snap ring using external snap ring pliers.

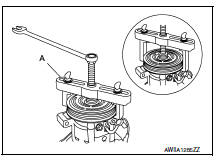

- Remove the pulley assembly using suitable tool (a).

Caution:

To prevent deformation of the pulley groove, the puller claws should be hooked under (not into) the pulley groove.

- Remove the magnet coil snap ring (a) using a suitable tool.

Then remove the magnet coil (1) from compressor shaft.

Inspection after removal

Clutch disc

If the contact surface shows signs of damage due to excessive heat, replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the contact surface of the pulley shows signs of excessive grooving, replace the clutch disc and pulley. The contact surfaces of the pulley assembly should be cleaned with a suitable solvent before installation.

Magnet Coil

Check the magnet coil for a loose connection or cracked insulation.

INSTALLATION

- Install the magnet coil.

CAUTION:

Be sure to align the magnet coil pin with the hole in the compressor front head.

- Install the magnet coil (1) on the compressor shaft with the snap ring (A) using suitable tool.

- Install the pulley assembly using the drive plate installer and a wrench, then install the snap ring using snap ring pliers.

Tool number : — (J-38873-A)

- Install the clutch disc on the drive shaft, together with the original shim(s). Press the clutch disc down using the drive plate installer.

- Install the center bolt using the clutch disc holding tool.

- After installation, check that the pulley rotates smoothly.

- Install the compressor. Refer to HA-31, "COMPRESSOR : Removal and Installation".

INSPECTION OF CLUTCH DISC TO PULLEY CLEARANCE

- Check the clearance around the entire periphery of the clutch disc.

Clutch disc to pulley clearance : 0.3 - 0.6 mm (0.01 - 0.02 in)

- If specified clearance is not obtained, replace compressor clutch.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engaging and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Cooler pipe and hose

Cooler pipe and hose

Exploded view

High-pressure service port

High-pressure pipe

Expansion valve

Low-pressure service port

Low-pressure flexible hose

Compressor

Refrigerant pressure sensor

Condenser ...

Other materials:

Removal and installation

Audio unit

Exploded view

Audio unit

Audio unit bracket (LH)

Audio unit bracket (RH)

Removal and installation

Removal

Disconnect the negative battery terminal. Refer to pg-50, "removal and

installation (battery)".

Remove cluster lid c lower. Refer to ip-20, "re ...

Drinking alcohol/drugs and driving

WARNINGNever drive under the influence of alcohol

or drugs. Alcohol in the bloodstream reduces

coordination, delays reaction time

and impairs judgement. Driving after

drinking alcohol increases the likelihood

of being involved in an accident injuring

yourself and others. Add ...

P0128 Thermostat function

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0128 is displayed with DTC P0300, P0301, P0302, P0303 or P0304,

first perform the trouble

diagnosis for P0300, P0301, P0302, P0303 or P0304. Refer to EC-269, "DTC Logic".

Engine coolant temperature has not risen enough to open the thermost ...