Nissan Sentra Service Manual: Clutch piping

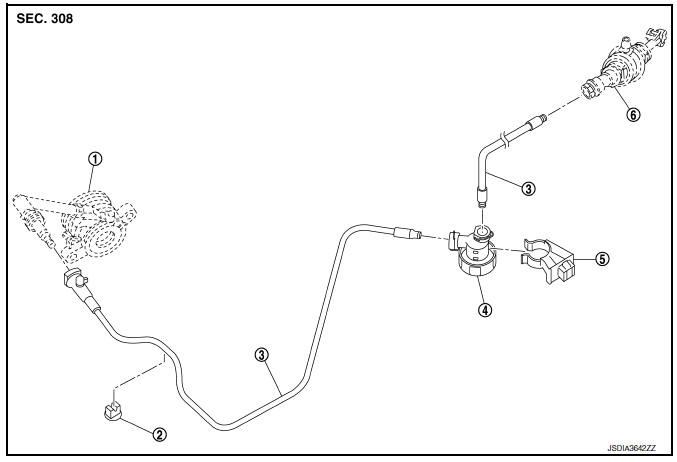

Exploded View

- CSC (Concentric Slave Cylinder)

- Clip

- Clutch tube

- Clutch damper

- Bracket

- Clutch master cylinder

Hydraulic Layout

- Clutch tube

- Lock pin

- CSC (Concentric Slave Cylinder)

- Clutch damper

- Clutch master cylinder

- Clutch pedal

Removal and Installation

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it spills, wipe up immediately and wash the affected area with water.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Drain clutch fluid. Refer to CL-7, "Draining".

- Press the lock pin into the bleeding connector of the CSC, and then remove clutch tube from CSC.

- Pull outward on the lock pins from the connectors of the clutch damper until the pins stop, and then remove clutch tubes from clutch damper.

- Pull outward on the lock pin from the connector of the clutch master cylinder until the pin stops, and then remove clutch tube from clutch master cylinder.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not damage clutch tube.

- Insert each clutch tube into the CSC bleeding connector, the clutch damper connector, and the clutch master cylinder connector until it contacts the end of each connector

- Install each lock pin into the clutch damper connector and the clutch master cylinder connector until it contacts the end of each connector.

Inspection and Adjustment

INSPECTION AFTER REMOVAL

- Check the clutch tube for cracks and damage. If the clutch tube has cracks or damage, replace it with a new one.

- Check the O-ring of the clutch tube for cracks and damage. If the O-ring of the clutch tube has cracks or damage, replace clutch tube with a new one.

CAUTION:

Do not reuse O-rings.

- Check the clutch damper for cracks and damage. If the clutch damper has cracks or damage, replace it with a new one.

INSPECTION AFTER INSTALLATION

- Check the fluid leakage and the fluid level. Refer to CL-7, "Inspection".

- Check the clutch pedal height. Refer to CL-5, "Inspection and Adjustment".

ADJUSTMENT AFTER INSTALLATION

Perform the air bleeding procedure. Refer to CL-9, "Air Bleeding".

Clutch master cylinder

Clutch master cylinder

Exploded View

Reservoir hose

Reservoir tank

Clutch master cylinder

Removal and Installation

REMOVAL

CAUTION:

Keep painted surface on the body or other parts free of clutch

flui ...

CSC(concentric slave cylinder)

CSC(concentric slave cylinder)

Exploded View

Transaxle assembly

CSC (Concentric Slave Cylinder)

Removal and Installation

CAUTION:

Do not reuse CSC (Concentric Slave Cylinder). The CSC slides back

to the origina ...

Other materials:

P0720 Output speed sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0720

OUTPUT SPEED SENSOR

(Output Speed Sensor Circuit)

The output speed sensor value is less than

150 rpm continuously for 5 seconds ...

Ipdm-e branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ipdm e/r for damage, bend and

loose connection (unit side

and connector side).

Is the inspection result normal?

Yes ...

Rear parcel shelf finisher

Exploded View

Seat belt finisher (RH)

Rear parcel shelf finisher

Rear seatback finisher (RH)

Top tether strap anchor finisher

(RH)

Top tether strap anchor finisher

(center)

Rear seatback finisher (LH)

Top tether strap anchor finisher

(LH)

Seat belt finisher (LH)

Seat b ...