Nissan Sentra Service Manual: Can communication circuit

Diagnosis procedure

1.Connector inspection

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Disconnect all the unit connectors on CAN communication system.

- Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.Check harness continuity (short circuit)

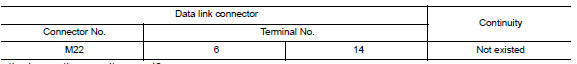

Check the continuity between the data link connector terminals.

Is the inspection result normal? Yes >> go to 3.

No >> check the harness and repair the root cause.

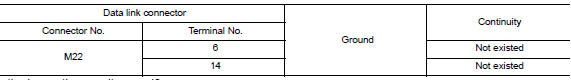

3.Check harness continuity (short circuit)

Check the continuity between the data link connector and the ground.

Is the inspection result normal? Yes >> go to 4.

No >> check the harness and repair the root cause.

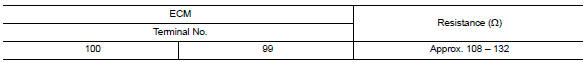

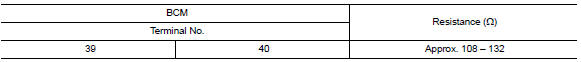

4.Check ecm and bcm termination circuit

- Remove the ecm and the bcm.

- Check the resistance between the ECM terminals.

- Check the resistance between the bcm terminals.

Is the measurement value within the specification? YES >> GO TO 5.

NO >> Replace the ECM and/or the BCM.

5.Check symptom

Connect all the connectors. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.Check unit reproduction

Perform the reproduction test as per the following procedure for each unit.

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Disconnect one of the unit connectors of can communication system.

Note:

Ecm and bcm have a termination circuit. Check other units first.

- Connect the battery cable to the negative terminal. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Note:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>connect the connector. Check other units as per the above procedure.

Non-reproduced>>replace the unit whose connector was disconnected.

Bcm branch line circuit

Bcm branch line circuit

Diagnosis Procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the BCM for damage, bend and ...

Can system (type 4)

Can system (type 4)

Dtc/circuit diagnosis ...

Other materials:

1144 Incomplete steering angle sensor adjustment

DTC Logic

Dtc detection logic

Dtc

Display item

Malfunction detected condition

Possible causes

C1144

St ang sen signal

When neutral position adjustment of steering angle

sensor is not complete.

Harness or connector

Steering angle sensor

Abs actu ...

P0863 TCM Communication

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0863

TCM COMMUNICATION

(TCM Communication Circuit)

An error is detected at the initial CAN diagnosis of TCM.

TCM

DTC CONFIRMATIO ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...