Nissan Sentra Service Manual: Can communication circuit

Diagnosis procedure

1.Connector inspection

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect all the unit connectors on can communication system.

- Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.Check harness continuity (short circuit)

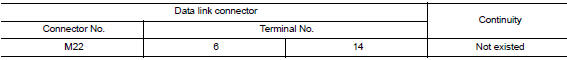

Check the continuity between the data link connector terminals.

Is the inspection result normal? Yes >> go to 3.

No >> check the harness and repair the root cause.

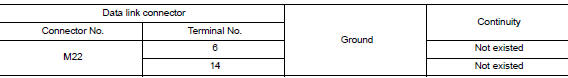

3.Check harness continuity (short circuit)

Check the continuity between the data link connector and the ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Check the harness and repair the root cause.

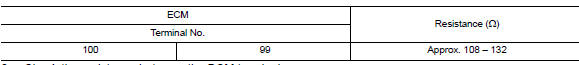

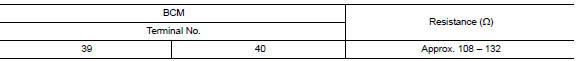

4.Check ecm and bcm termination circuit

- Remove the ECM and the BCM.

- Check the resistance between the ecm terminals.

- Check the resistance between the bcm terminals.

Is the measurement value within the specification? Yes >> go to 5.

No >> replace the ecm and/or the bcm.

5.Check symptom

Connect all the connectors. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Inspection result

Reproduced>>go to 6.

Non-reproduced>>start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.Check unit reproduction

Perform the reproduction test as per the following procedure for each unit.

- Turn the ignition switch off

- Disconnect the battery cable from the negative terminal.

- Disconnect one of the unit connectors of can communication system.

Note:

Ecm and bcm have a termination circuit. Check other units first.

- Connect the battery cable to the negative terminal. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Note:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>connect the connector. Check other units as per the above procedure.

Non-reproduced>>replace the unit whose connector was disconnected.

Bcm branch line circuit

Bcm branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the BCM for damage, bend and ...

Can system (type 3)

Can system (type 3)

Dtc/circuit diagnosis ...

Other materials:

Power window main switch

Reference Value

TERMINAL LAYOUT

PHYSICAL VALUES

MAIN POWER WINDOW AND DOOR LOCK/UNLOCK SWITCH

Fail Safe

FAIL-SAFE CONTROL

Switches to fail-safe control when malfunction is detected in encoder signal

that detects up/down speed and

direction of door glass. Switches to fail-safe co ...

Steering wheel

Inspection

CONDITION OF INSTALLATION

Check installation condition of power steering gear

assembly, front suspension, front drive shaft and steering

column.

Check if movement exists when steering wheel is moved up and

down, to the left and right and to the axial

direction.

S ...

Jump starting

To start your engine with a booster battery, the

instructions and precautions below must be followed.

WARNING

If done incorrectly, jump starting can

lead to a battery explosion, resulting in

severe injury or death. It could also

damage your vehicle.

Explosive hydrogen ga ...