Nissan Sentra Service Manual: Can communication circuit

Diagnosis procedure

1.CONNECTOR INSPECTION

- Turn the ignition switch OFF.

- Disconnect the battery cable from the negative terminal.

- Disconnect all the unit connectors on CAN communication system.

- Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHeck harness continuity (short circuit)

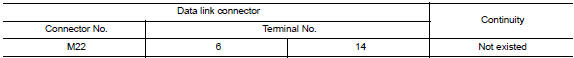

Check the continuity between the data link connector terminals.

Is the inspection result normal? Yes >> go to 3.

No >> check the harness and repair the root cause.

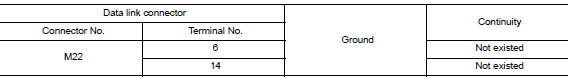

3.Check harness continuity (short circuit)

Check the continuity between the data link connector and the ground.

Is the inspection result normal? Yes >> go to 4.

No >> check the harness and repair the root cause.

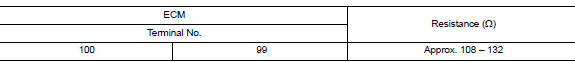

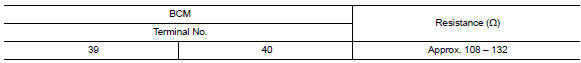

4.Check ecm and bcm termination circuit

- Remove the ecm and the bcm.

- Check the resistance between the ECM terminals.

- Check the resistance between the bcm terminals.

Is the measurement value within the specification? Yes >> go to 5.

No >> replace the ecm and/or the bcm.

5.Check symptom

Connect all the connectors. Check if the symptoms described in the “symptom (results from interview with customer)” are reproduced.

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is detected.

6.Check unit reproduction

- Perform the reproduction test as per the following procedure for each unit.

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Disconnect one of the unit connectors of can communication system.

Note:

Ecm and bcm have a termination circuit. Check other units first.

- Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom (Results from interview with customer)” are reproduced.

Note:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>connect the connector. Check other units as per the above procedure.

Non-reproduced>>replace the unit whose connector was disconnected.

Bcm branch line circuit

Bcm branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the bcm for damage, bend and ...

Can system (type 2)

Can system (type 2)

Dtc/circuit diagnosis ...

Other materials:

USB interface (models with Navigation System)

Connecting a device to the USB input

jack

WARNINGDo not connect, disconnect, or operate the

USB device while driving. Doing so can be

a distraction. If distracted you could lose

control of your vehicle and cause an accident

or serious injury.

CAUTION

Do not force t ...

Rear seat belt

Exploded View - Seat Belt Retractor

Seat belt retractor (RH)

Seat belt retractor (center)

Seat belt retractor (LH)

Front

Removal and Installation - Seat Belt Retractor

REMOVAL

Remove the rear parcel shelf finisher. Refer to INT-33, "Removal and

Installation".

Re ...

Vehicle security system (if so equipped)

The vehicle security system provides visual and

audible alarm signals if someone opens the doors

when the system is armed. It is not, however, a

motion detection type system that activates when

a vehicle is moved or when a vibration occurs.

The system helps detect vehicle theft but cannot

prev ...