Nissan Sentra Service Manual: Camshaft valve clearance

Inspection and Adjustment

INSPECTION

Perform inspection after removal, installation or replacement of camshaft or valve-related parts, or if there are unusual engine conditions regarding valve clearance.

- Remove rocker cover. Refer to EM-46, "Exploded View".

- Measure the valve clearance with the following procedure:

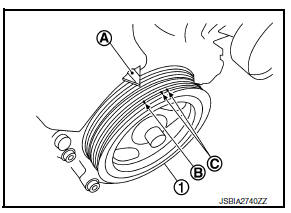

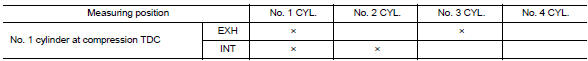

- Set No. 1 cylinder at TDC of its compression stroke.

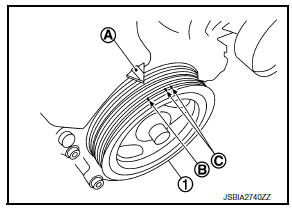

- Rotate crankshaft pulley (1) clockwise and align TDC mark (no paint) (B) to timing indicator (A) on front cover.

(C) : White paint mark (Not used for service)

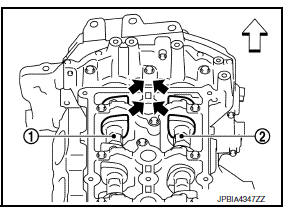

- At this time, check that both intake and exhaust cam lobes of

No. 1 cylinder face inside (

)

)

as shown.

(1) : Camshaft (INT)

(2) : Camshaft (EXH)

: Engine front

: Engine front

- If they do not face inside, rotate crankshaft pulley once more (360 degrees) and align as shown.

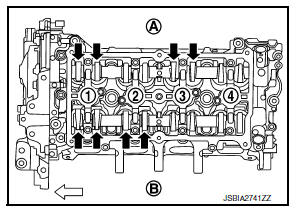

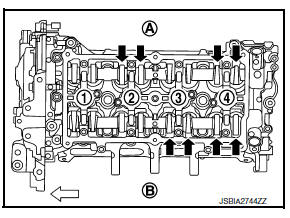

- Measure the clearance between valve lifter and camshaft using suitable tool as shown.

Valve clearance : Refer to EM-119, "Camshaft".

- Measure the valve clearances at locations marked “×” [locations

indicated with black arrow (

![)] as shown using suitable](images/books/349/2/index119.gif)

)] as shown using suitable tool.

(A) : Exhaust side

(B) : Intake side

(1) : No. 1 cylinder

(2) : No. 2 cylinder

(3) : No. 3 cylinder

(4) : No. 4 cylinder

Engine front

Engine front

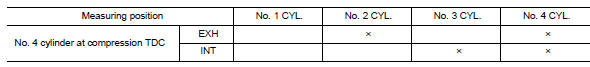

- Set No. 4 cylinder at TDC of its compression stroke.

- Rotate crankshaft pulley (1) one revolution (360 degrees) and align TDC mark (no paint) (B) to timing indicator (A) on front cover.

(C) : White paint mark (Not used for service)

- Measure the valve clearance at locations marked “×” [locations

indicated with black arrow (

)]

)]

as shown using suitable tool.

(A) : Exhaust side

(B) : Intake side

(1) : No. 1 cylinder

(2) : No. 2 cylinder

(3) : No. 3 cylinder

(4) : No. 4 cylinder

: Engine front

: Engine front

- If out of standard, perform adjustment. Refer to “ADJUSTMENT”.

ADJUSTMENT

- Perform adjustment depending on selected head thickness of valve lifter.

- Remove camshaft. Refer to EM-60, "Exploded View".

- Remove valve lifters at the locations that are out of the standard.

- Measure the center thickness of the removed valve lifters using suitable tool (A).

- Use the equation below to calculate valve lifter thickness for replacement.

Valve lifter thickness calculation: t = t1 + (C1 – C2)

t = Valve lifter thickness to be replaced

t1 = Removed valve lifter thickness

C1 = Measured valve clearance

C2 = Standard valve clearance:

-

Intake : 0.29 mm (0.011 in)

-

Exhaust : 0.32 mm (0.013 in)

- Thickness of new valve lifter (B) can be identified by stamp mark (A) on the reverse side (inside the cylinder).

- Stamp mark “302” indicates 3.02 mm (0.1189 in) in thickness.

NOTE:

Available thickness of valve lifter: 26 sizes range 3.00-3.50 mm (0.1181-0.1378 in) in steps of 0.02 mm (0.0008 in) (when manufactured at factory). Refer to EM-119, "Camshaft".

- Install the selected valve lifter.

- Install camshaft. Refer to EM-60, "Exploded View".

- Install timing chain and related parts. Refer to EM-48, "Exploded View".

- Manually rotate crankshaft pulley a few rotations.

- Check that the valve clearances are within the standard. Refer to “INSPECTION”.

- Installation of remaining components is in the reverse order of removal.

- Warm up the engine, and check for unusual noise and vibration.

Air cleaner filter

Air cleaner filter

Exploded View

Mass air flow sensor

Mass air flow gasket

Clamp

Air duct (suction side)

Resonator

Clamp

PCV hose

Clamp

Clamp

Air cleaner cover

Mounting rubber

Air cleaner f ...

Compression pressure

Compression pressure

Inspection

Warm up the engine to full operating temperature.

Release fuel pressure. Refer to EC-143, "Work Procedure".

Remove ignition coil and spark plug from each cylinder. Refer t ...

Other materials:

Windshield glass

Exploded View

Windshield glass molding

Spacer

Rubber dam

Windshield glass

Windshield insulator

Front pillar finisher

Instrument panel

Cowl top cover

Roof panel

Cowl top

Body side outer

Headlining

Adhesive

12 +2.0 mm (0.5 +0.08 in)

7 +2.0 mm (0.3 +0.08 in)

...

P0078 EVT Control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0078

EX V/T ACT/CIRC-B1

(Exhaust valve control solenoid circuit

bank 1)

An improper voltage is sent to the ECM

through exhaust v ...

The steering switch (meter control switch) is inoperative

Description

If any of the following malfunctions is found for the steering switch (meter

control switch) operation.

All switches are inoperative

The specified switch cannot be operated

Diagnosis procedure

1.Check steering switch signal circuit

Check the steering switch signal circuit. ...