Nissan Sentra Service Manual: Brake booster

Inspection

Operation

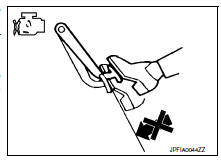

Depress the brake pedal several times at five second intervals with the engine stopped. Start the engine with the brake pedal fully depressed. Check that the clearance between brake pedal and dash lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. This is normal brake system operation.

Vacuum Inspection

Idle the engine for one minute to apply vacuum to the brake booster.

Stop the engine. Depress the brake pedal several times at five second intervals until the accumulated vacuum is released to atmospheric pressure. Check that the clearance between brake pedal and dash lower panel gradually increases (A → B → C) each time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the engine while holding down the brake pedal. Check that the brake pedal stroke does not change after holding down the brake pedal for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the brake pedal is fully depressed. This is normal brake system operation.

Brake master cylinder

Brake master cylinder

Inspection

Check for brake fluid leakage at the following areas:

Master cylinder mounting face

Reservoir tank mounting face

Brake tube and brake tube connections

Brake hose and brake hose ...

Front disc brake

Front disc brake

BRAKE PAD

BRAKE PAD : Inspection

PAD WEAR

Check brake pad thickness from an inspection hole on caliper body.

Check using a scale if necessary

Wear limit thickness : Refer to BR-55, "Front ...

Other materials:

Front fog lamp

Aiming adjustment

PREPARATION BEFORE ADJUSTING

The fog lamp is a semi-sealed beam type which uses a replaceable halogen

bulb. Before performing aiming

adjustment procedure, check the following:

Ensure all tires are inflated to correct pressure.

Place vehicle and screen on level surface.

...

Dtc/circuit diagnosis

U1000 can comm

Description

Refer to LAN-7, "CAN COMMUNICATION SYSTEM : System Description".

Dtc logic

Dtc detection logic

Note:

U1000 can be set if a module harness was disconnected and reconnected,

perhaps during a repair. Confirm

that there are actual can diagnostic symptoms and ...

Intermittent Incident

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for

service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No

Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the conditions/env ...