Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

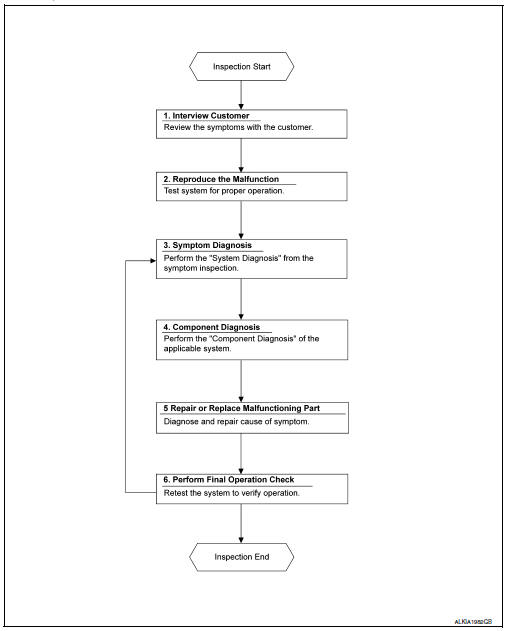

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3.

3. IDENTIFY THE MALFUNCTIONING SYSTEM WITH SYMPTOM DIAGNOSIS

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms. Refer to WW-46, "Symptom Table".

>> GO TO 4.

4. PERFORM THE COMPONENT DIAGNOSIS OF THE OF THE APPLICABLE SYSTEM

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6.

6. FINAL CHECK

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? YES >> Inspection End.

NO >> GO TO 3.

Wiring diagram

Wiring diagram

Wiper and washer system

Wiring diagram - with intelligent key

Wiring diagram - without intelligent key

...

Other materials:

C1116 Stop lamp switch

DTC Logic

DTC DETECTION LOGIC

DTC

Display item

Malfunction detected condition

Possible cause

C1116

STOP LAMP SW

When stop lamp switch circuit is open.

Harness or connector

Stop lamp switch

ABS actuator and electric unit

(control unit)

...

Tow Truck Towing

NISSAN recommends that vehicle be towed with driving (front) wheels off the

ground or that a dolly be used.

CVT: Continuously Variable Transmission

M/T: Manual transmission

CAUTION:

All applicable state or Provincial laws and local laws regarding

the towing operation must be ...

Mixture ratio self-learning value

clear

Description

This describes how to erase the mixture ratio self-learning value. For the

actual procedure, follow the instructions

in “Diagnosis Procedure”.

Work Procedure

1.START

With CONSULT

Start engine and warm it up to normal operating temperature.

Select “SELF-LEARNI ...