Nissan Sentra Service Manual: Abs actuator and electric unit (control unit)

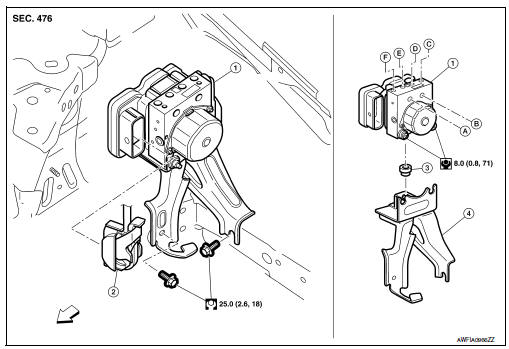

Exploded View

-

ABS actuator and electric unit (control unit)

-

ABS actuator and electric unit (control unit) harness connector

-

Bushing

-

Bracket

-

To master cylinder secondary side

-

To master cylinder primary side

-

To rear LH caliper

-

To front RH caliper

-

To front LH caliper

-

To rear RH caliper

Front

Front

Removal and Installation

REMOVAL

-

Disconnect battery negative terminal. Refer to PG-50, "Exploded View".

-

Drain brake fluid. Refer to BR-17, "Drain and Refill".

-

Remove the cowl top. Refer to EXT-26, "Removal and Installation".

-

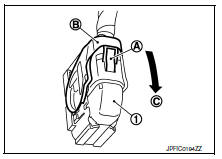

Disconnect ABS actuator and electric unit (control unit) harness connector (1), follow the procedure described below.

-

Push the pawl (A).

-

Move the lever (B) in the direction (C) until locked.

-

Disconnect ABS actuator and electric unit (control unit) harness connector.

-

Loosen flare nut of brake tube using a flare nut wrench, and then remove brake tube from ABS actuator and electric unit (control unit). Refer to BR-25, "FRONT : Exploded View".

-

Remove ABS actuator and electric unit (control unit) and bracket.

-

Remove bracket and bushing from ABS actuator and electric unit (control unit).

INSTALLATION

Installation is in the reverse order of removal.

-

When replacing with a new ABS actuator and electric unit (control unit), do not remove the protector of the brake tube mounting hole until right before the brake tube is installed.

-

When installing brake tube, tighten to the specified torque using a flare nut torque wrench so that flare nut and brake tube are not damaged. Refer to BR-25, "FRONT : Exploded View".

-

Do not remove and install ABS actuator and electric unit (control unit) by holding actuator harness.

-

Bleed air from brake piping after installation. Refer to BR-17, "Bleeding Brake System".

-

Do not apply excessive impact to actuator, such as by dropping it.

-

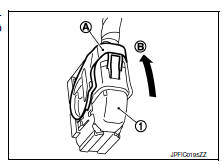

After installing the ABS actuator and electric unit (control unit) harness connector (1), move the lever (A) in the direction (B) to secure the locking.

Sensor rotor

Sensor rotor

Front sensor rotor

FRONT SENSOR ROTOR : Removal and Installation

The front wheel sensor rotor is an integral part of the wheel

hub and bearing assembly and cannot be disassembled.

Refer to FAX- ...

VDC off switch

VDC off switch

Removal and Installation

REMOVAL

Remove the instrument lower panel LH. Refer to IP-21,

"Removal and Installation".

Remove the switch plate screws and remove the switch plate. ...

Other materials:

Fender protector

Fender protector

Fender protector : exploded view

Front fender protector

Front wind deflector

U nut

Rivet

Grommet

Front

Fender protector : removal and installation - front fender protector

REMOVAL

Remove front wheel and tire. Refer to WT-47, "Adjustment".

...

Maintenance precautions

When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed.

WARNING

Park the vehicle on a level surface, apply

...

Eps branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the eps control unit for damage,

bend and loose connection (unit

side and connector side).

Is the inspection result norm ...