Nissan Sentra Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW CUSTOMER

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.SYMPTOM CHECK

Verify symptoms.

>> GO TO 3.

3.CHECK FOR DTCS

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Self Diagnostic Result” mode of “HVAC” using CONSULT.

- Check DTC.

Is any DTC detected? YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM DTC DIAGNOSTIC PROCEDURE

Perform the diagnostic procedure for the detected DTC. Refer to HAC-37, "DTC Inspection Priority Chart".

>> GO TO 7.

5.OPERATION CHECK

Perform the operation check. Refer to HAC-53, "Work Procedure".

>> GO TO 6.

6.SYMPTOM DIAGNOSIS

Check the symptom diagnosis table. Refer to HAC-97, "Diagnosis Chart By Symptom".

>> GO TO 8.

7.VERIFY REPAIR

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Self Diagnostic Result” mode of “HVAC” using CONSULT

- Check DTC.

Is any DTC detected? YES >> GO TO 4.

NO >> GO TO 8.

8.PERFORM FINAL OPERATION CHECK

Perform the operation check. Refer to HAC-53, "Work Procedure".

Does it operate normally? YES >> Inspection End.

NO >> GO TO 2.

OPERATION INSPECTION

Work Procedure

DESCRIPTION

The purpose of the operational check is to check that the individual system operates normally.

Conditions : Engine running at normal operating temperature

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

- Start the engine.

- Operate the temperature control switch (driver side) and raise the temperature setting to 32В°C (90В°F).

- Press the OFF switch

- Turn the ignition switch OFF.

- Turn the ignition switch ON.

- Press the AUTO switch.

- Check that the temperature setting, before turning the ignition switch OFF, is stored.

Is the inspection result normal? YES >> GO TO 2.

NO >> Check power and ground circuits for A/C auto amp. Refer to HAC-83, "A/C AUTO AMP. : Diagnosis Procedure".

2.CHECK BLOWER MOTOR SPEED

- Operate the fan control dial. Check that the fan speed changes.

- Check the operation for all fan speeds.

Is the inspection result normal? YES >> GO TO 3.

NO >> Check blower motor system. Refer to HAC-90, "Diagnosis Procedure".

3.CHECK DISCHARGE AIR (MODE SWITCH AND DEF SWITCH)

- Press the MODE switch and the DEF switch.

- Check that the air outlets change according to each indicated air outlet by placing a hand in front of the outlets. Refer to HAC-12, "System Description".

NOTE:

Confirm that the A/C compressor clutch is engaged (sound or visual

inspection) and intake door position is at

FRE ( ) when the D/F (

) when the D/F (

) or DEF (  ) is selected.

) is selected.

Is the inspection result normal? YES >> GO TO 4.

NO >> Check mode door system. Refer to HAC-77, "Diagnosis Procedure".

4.CHECK INTAKE AIR

- Press the REC (

) switch.

) switch.

Indicator is turned ON. - Press the FRE (

) switch.

) switch.

Indicator is turned ON. - Listen for the intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the A/C compressor clutch is engaged (sound or visual

inspection) and the FRE ( ) switch

) switch

is

pressed when the D/F ( ) or DEF (

) or DEF (

) is selected.

Is the inspection result normal? YES >> GO TO 5.

NO >> Check intake door system. Refer to HAC-79, "Diagnosis Procedure".

5.CHECK A/C SWITCH

- Press the A/C switch.

- The A/C switch indicator is turned ON.

Confirm that the A/C compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check magnet clutch system. Refer to HAC-94, "Diagnosis Procedure".

6.CHECK TEMPERATURE DECREASE

- Operate the A/C compressor.

- Operate the temperature control switch (driver side) and lower the temperature setting to 18В°C (60В°F).

- Check that the cool air blows from the outlets.

Is the inspection result normal? YES >> GO TO 7.

NO >> Check for insufficient cooling. Refer to HAC-99, "Diagnosis Procedure".

7.CHECK TEMPERATURE INCREASE

- Operate the temperature control switch (driver side) and raise the temperature setting to 32В°C (90В°F) after warming up the engine.

- Check that the warm air blows from the outlets.

Is the inspection result normal? YES >> GO TO 8.

NO >> Check for insufficient heating. Refer to HAC-101, "Diagnosis Procedure".

8.CHECK DUAL MODE FUNCTION

- Press the DUAL mode switch, and then check that “DUAL” is shown on the display.

- Operate the temperature control switch (driver side). Check that the discharge air temperature (driver side) changes.

- Operate the temperature control switch (passenger side). Check that the discharge air temperature (passenger side) changes.

- Press the DUAL mode switch, and then check that the temperature setting (driver/passenger) is unified to the driver side temperature setting.

Is the inspection result normal? YES >> GO TO 9.

NO >> Refer to HAC-97, "Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

9.CHECK AUTO MODE

- Press the AUTO switch, and then check that “AUTO” is shown on the display.

- Operate the temperature control switch (driver side). Check that the fan speed, outlet air or intake air changes. The discharge air temperature or fan speed varies depending on the ambient temperature, invehicle temperature, and temperature setting.

Is the inspection result normal? YES >> Inspection End

NO >> Refer to HAC-97, "Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

SYSTEM SETTING

Temperature Setting Trimmer

Description

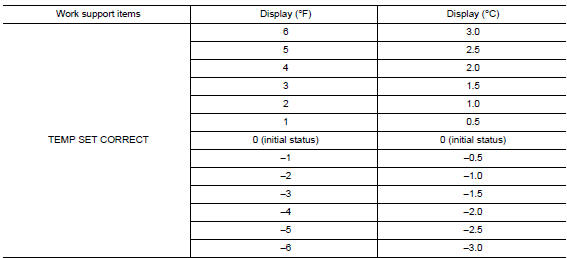

If the temperature felt by the customer is different than the airflow temperature controlled by the temperature setting, the auto amplifier control temperature can be adjusted to compensate for the temperature setting.

How to set

Using CONSULT, perform “TEMP SET CORRECT” in “WORK SUPPORT” of HVAC.

NOTE:

- When the temperature setting is set to 25.0В°C (77В°F) and −3.0В°C (−6В°F), the temperature controlled by auto amp is 25.0В°C (77В°F) − 3.0В°C (6В°F) = 22.0В°C (71В°F) and the temperature becomes lower than the temperature setting.

- When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10V or less, the setting of the difference between the temperature setting and control temperature may be cancelled.

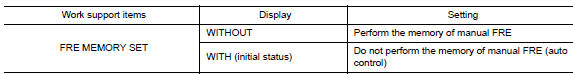

Inlet Port Memory Function (FRE)

Description

- If the ignition switch is turned to the OFF position while the FRE (

) switch is set to ON (fresh

) switch is set to ON (fresh

air intake), “Perform the memory” or “Do not perform the memory” of the FRE ( )

)

switch ON (fresh air intake) condition can be selected. - If “Perform the memory” was set, the FRE (

) switch will be ON (fresh air intake) when turning the ignition switch to the ON position again. - If “Do not perform the memory” was set, the air inlets will be controlled automatically when turning the ignition switch to the ON position again.

How to set

Using CONSULT, perform “FRE MEMORY SET” in “WORK SUPPORT” of HVAC.

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10V or less, the setting of the FRE switch memory function may be cancelled.

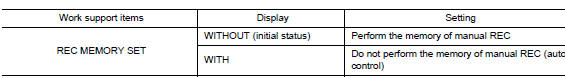

Inlet Port Memory Function (REC)

Description

- If the ignition switch is turned to the OFF position while the REC (

) switch is set to ON (recirculation), “Perform the memory” or “Do not perform the memory” of the REC ( ) switch ON (recirculation)

) switch ON (recirculation)

condition can be selected. - If “Perform the memory” was set, the REC (

) switch will be ON (recirculation) when turning the ignition switch to the ON position again. - If “Do not perform the memory” was set, the air inlets will be controlled automatically when turning the ignition switch to the ON position again.

How to set

Using CONSULT, perform “REC MEMORY SET” in “WORK SUPPORT” of HVAC.

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10V or less, the setting of the REC switch memory function may be cancelled.

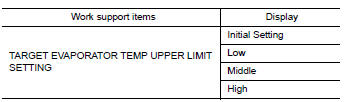

Target Evaporator Temp Upper Limit

DESCRIPTION

Set the target evaporator temperature upper limit.

HOW TO SET

With CONSULT

With CONSULT

Perform the “TARGET EVAPORATOR TEMP UPPER LIMIT SETTING” of HVAC work support item.

DOOR MOTOR STARTING POSITION RESET

Description

- Reset signal is transmitted from A/C auto amp. to air mix door motor and mode door motor. Starting position reset can be performed.

NOTE:

During reset, DEF switch indicator blinks.

- When air mix door motor or mode door motor is removed and installed, always perform door motor starting position reset.

Work Procedure

1.PERFORM DOOR MOTOR STARTING POSITION RESET

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “Door Motor Starting Position Reset” in “ACTIVE TEST” mode of “HVAC” using CONSULT.

- Touch “Start” and wait a few seconds.

- Make sure the “COMPLETED” is displayed on CONSULT screen.

>> Inspection End

Wiring diagram

Wiring diagram

AUTOMATIC AIR CONDITIONING SYSTEM

Wiring Diagram

...

DTC/circuit diagnosis

DTC/circuit diagnosis

U1000 CAN COMM CIRCUIT

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data com ...

Other materials:

Brake master cylinder

Exploded View

Reservoir cap

Oil strainer

Reservoir tank

Cylinder body

Pin

O-ring

Grommet

Apply brake fluid

PBC (Poly Butyl Cuprysil)

grease or

silicone-based grease

Removal and Installation

REMOVAL

CAUTION:

Do not spill or splash brake fluid on painted surfaces. ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...

NISSAN Vehicle Immobilizer System keys

You can only drive your vehicle using the master

keys which are registered to the NISSAN Vehicle

Immobilizer System components in your vehicle.

These keys have a transponder chip in the key

head.

The master key can be used for all the locks.

Never leave these keys in the vehicle.

Addition ...