Nissan Sentra Service Manual: Vacuum lines

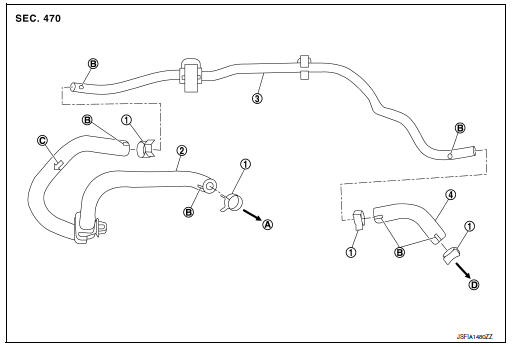

Exploded View

- Clamp

- Vacuum hose (built-in check valve)

- Vacuum piping

- Vacuum hose

- To intake manifold side

- Paint mark

- Stamp indicating engine direction

- To brake booster

Removal and Installation

REMOVAL

- Remove air duct and air cleaner case. Refer to EM-25, "Removal and Installation".

- Remove the vacuum hoses and vacuum piping.

INSPECTION AFTER REMOVAL

Visual Inspection

Check for correct installation, damage and deterioration of the vacuum hoses and pipe.

Valve Air-tightness Check

- Connect a suitable tool at each end of the vacuum hose with built-in check valve to inspect the check valve operation.

Vacuum applied at booster end : Refer to BR-54, "Check Valve".

Vacuum applied at intake manifold end : Refer to BR-54, "Check Valve".

- Replace the vacuum hose with built-in check valve if out of specification.

INSTALLATION

Installation is in the reverse order of removal.

- When installing vacuum hose, insert it until its tip reaches the back-end of length (A) or further as shown.

CAUTION:

Do not use lubricating oil during assembly

Length (A) : 24 mm (0.95 in) or more

- Face the paint mark of vacuum hose (build-in check valve) (intake manifold side) to vehicle right side to assemble.

- Face the paint mark of vacuum hose (build-in check valve) (brake booster side) to vehicle front side to assemble.

- Face the paint mark of vacuum piping (intake manifold side) to vehicle front side to assemble.

- Face the paint mark of vacuum piping (brake booster side) to downward to assemble.

- Face the paint mark of vacuum hose (intake manifold side) to downward to assemble.

- Face the paint mark of vacuum hose (brake booster side) to vehicle front side to assemble.

- For clamp mounting direction (the orientation of pawl), refer to BR-36, "Exploded View".

Brake booster

Brake booster

Exploded View

Master cylinder assembly

Brake booster

Lock nut

Clevis

Gasket

Spacer

Removal and installation

REMOVAL

Remove cowl top and cowl top extension. Refer to EXT-26, ...

Front disc brake

Front disc brake

BRAKE PAD

BRAKE PAD : Exploded View

Cylinder body

Inner shim cover

Inner shim

Inner pad (with pad wear sensor)

Pad retainer

Torque member

Outer pad

Outer shim

Outer shim cover ...

Other materials:

Rear power window switch

Removal and Installation

REMOVAL

Release the pawls using a suitable tool and lift the rear power window

switch and finisher as an assembly

and remove

Disconnect the harness connector from the rear power window switch.

Release the pawl (one on each side) using a suitable tool, then

se ...

Abs actuator and electric unit (control unit)

Exploded View

ABS actuator and electric unit (control

unit)

ABS actuator and electric unit (control

unit) harness connector

Bushing

Bracket

To master cylinder secondary side

To master cylinder primary side

To rear LH caliper

To front RH caliper

...

Trunk room trim

Exploded View

Trunk floor trim

Trunk front floor spacer (LH)

Trunk side finisher (LH)

Reflector box assembly*

Trunk rear plate

Trunk side finisher (RH)

Trunk front floor spacer (RH)

Clip

Pawl

Trunk rear plate

TRUNK REAR PLATE : Removal and Installation

REMOVAL

Remove ...