Nissan Sentra Service Manual: Steering gear and linkage

Inspection

INSPECTION AFTER DISASSEMBLY

BOOT

-

Check boot for cracks. Replace if any damage is found.

STEERING GEAR ASSEMBLY HOUSING

-

Check steering gear assembly housing for damage and scratches. Replace if there are any abnormal conditions.

OUTER SOCKET AND INNER SOCKET

Ball joint swinging torque

-

Hook a spring balance to the ball stud and inner socket measuring point (*) and pull the spring balance. Make sure that the spring balance reads the specified value when ball stud and inner socket start to move. Replace outer socket and inner socket if they are outside the specification.

Tool number : — (J-44372)

Swinging torque : Refer to ST-19, "Power Steering Gear".

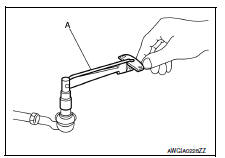

Ball joint rotating torque

-

Make sure that the reading is within the following specified range using Tool. Replace outer socket if the reading is outside the specification.

Tool number (A) : ST3127S000 (J-25765-A)

Rotating torque : Refer to ST-19, "Power Steering Gear".

INSPECTION AFTER INSTALLATION

-

Check if steering wheel turns smoothly when it is turned several times fully to the end of the left and right.

-

Check the steering wheel play, neutral position steering wheel, steering wheel turning force, and front wheel turning angle.

-

Steering wheel play: Refer to ST-5, "Inspection".

-

Neutral position steering wheel, steering wheel turning force, and front wheel turning angle: Refer to ST-5, "Inspection".

Steering column

Steering column

Inspection

STEERING COLUMN ASSEMBLY

Check each part of steering column assembly for damage or

other malfunctions. Replace entire steering column

assembly if any parts are damaged.

Me ...

Symptom diagnosis

Symptom diagnosis

Noise, vibration and harshness (NVH) troubleshooting

NVH Troubleshooting Chart

Use the chart below to find the cause of the symptom. If

necessary, repair or replace these parts.

×: Appl ...

Other materials:

P0500 VSS

EXCEPT FOR M/T MODELS

EXCEPT FOR M/T MODELS : Description

ECM receives vehicle speed signals from two different paths via CAN

communication line: One is from the

ABS actuator and electric unit (control unit) via the combination unit and the

other is from TCM.

EXCEPT FOR M/T MODELS : DTC Logi ...

Unit removal and installation

TRANSAXLE ASSEMBLY

Exploded View

Transaxle assembly

Refer to INSTALLATION

Removal and Installation

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns

could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap. ...

Diagnosis and repair workflow

Work flow

Overall sequence

Detailed flow

1. Obtain information about symptom

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2. Confirm concern

Check the malfunction on the veh ...