Nissan Sentra Service Manual: Power supply and ground circuit

Body control system

Body control system : diagnosis procedure

Regarding wiring diagram information, refer to bcs-51, "wiring diagram".

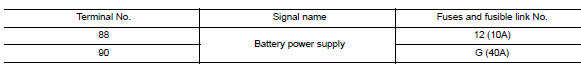

1.Check fuses and fusible link

Check that the following fuses and fusible link are not blown.

Is the fuse blown? Yes >> replace the blown fuse or fusible link after repairing the affected circuit.

No >> go to 2.

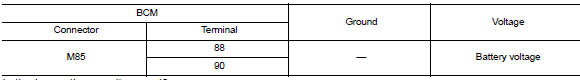

2.Check power supply circuit

- Disconnect BCM connector M85.

- Check voltage between bcm connector m85 and ground.

Is the inspection result normal? Yes >> go to 3.

No >> repair harness or connector.

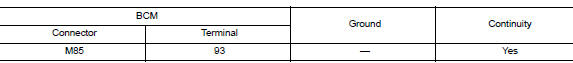

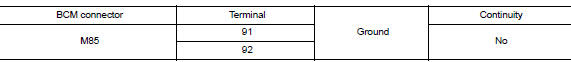

3.Check ground circuit

Check continuity between BCM connector M85 and ground.

Is the inspection result normal? Yes >> inspection end.

No >> repair harness or connector.

Moonroof motor assembly

Moonroof motor assembly : description

- Bcm supplies power.

- Cpu is integrated in moonroof motor assembly.

- Tilts up/down & slides open/close by moonroof switch operation.

- In order to close moonroof lid certainly with the signal from combination meter at the time of high speed run, the moonroof motor torque at the time of tilt-down operation is controlled.

Moonroof motor assembly : component function check

1. Check moonroof motor function

Check whether tilt up/down & slide open/close functions operate with moonroof switch normally? Is the inspection result normal? YES >> Moonroof motor assembly is OK.

NO >> Refer to RF-20, "MOONROOF MOTOR ASSEMBLY : Diagnosis Procedure".

Moonroof motor assembly : diagnosis procedure

Regarding wiring diagram information, refer to rf-13, "wiring diagram".

Moonroof motor assembly

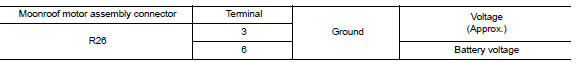

1. Check power supply circuit

- Turn ignition switch off.

- Disconnect moonroof motor assembly connector.

- Turn ignition switch on.

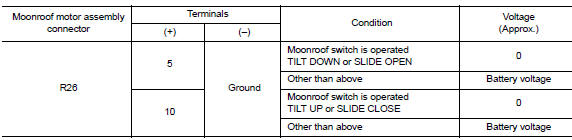

- Check voltage between moonroof motor assembly connector r26 and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 3.

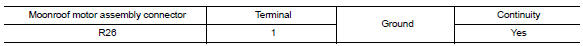

2. Check ground circuit

- Turn ignition switch off.

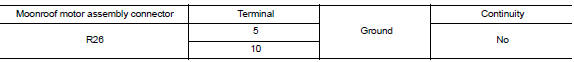

- Check continuity between moonroof motor assembly connector R26 and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace the harness or connectors.

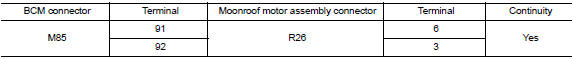

3. Check moonroof motor circuit

- Turn ignition switch off.

- Disconnect bcm.

- Check continuity between bcm connector m85 and moonroof motor assembly connector r26.

- Check continuity between BCM connector M85 and ground.

Is the inspection result normal? Yes >> go to 4.

NO >> Repair or replace the harness or connectors.

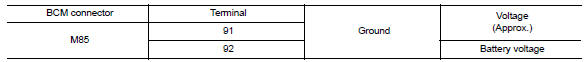

4. Check bcm power supply

- Connect bcm.

- Check voltage between BCM connector M85 and ground.

Is the inspection result normal? Yes >> check condition of harness and connectors.

No >> replace bcm. Refer to bcs-73, "removal and installation".

5. Check moonroof switch input signal

- Connect moonroof motor assembly.

- Turn ignition switch on.

- Check voltage between moonroof motor assembly connector R26 and ground.

Is the inspection result normal? Yes >> go to 8.

No >> go to 6.

6. Check moonroof switch circuit

- Turn ignition switch off.

- Disconnect moonroof motor assembly and moonroof switch.

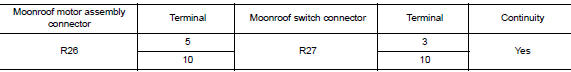

- Check continuity between moonroof motor assembly connector r26 and moonroof switch connector r27.

- Check continuity between moonroof motor assembly connector r26 and ground.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace the harness and connectors.

7. Check moonroof switch ground circuit

- Connect moonroof motor assembly.

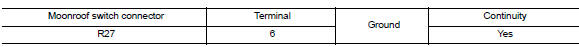

- Check continuity between moonroof switch connector r27 and ground.

Is the inspection result normal? Yes >> refer to rf-22, "moonroof motor assembly : component inspection".

No >> repair or replace the harness or connectors.

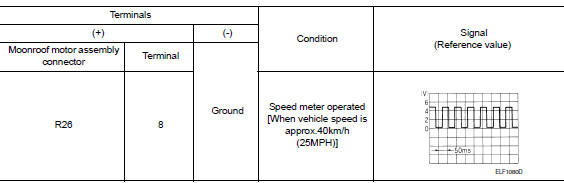

8. Check combination meter signal

- Check signal between moonroof motor assembly connector R26 and ground with oscilloscope.

Is the inspection result normal? Yes >> replace moonroof motor assembly. Refer to rf-41, "removal and installation". After that, refer to rf-18, "additional service when replacing control unit : special repair requirement".

No >> go to 9.

9.Check combination meter circuit

- Turn ignition switch OFF.

- Disconnect combination meter.

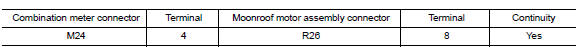

- Check continuity between combination meter connector m24 and moonroof motor assembly connector r26.

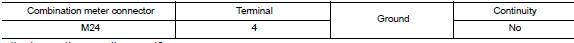

- Check continuity between combination meter connector M24 and ground.

Is the inspection result normal? Yes >> replace combination meter. Refer to mwi-77, "removal and installation".

No >> repair or replace the harness or connectors.

Moonroof motor assembly : component inspection

Moonroof switch

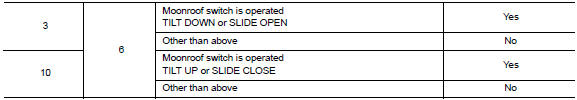

1. Check moonroof switch

- Turn ignition switch off.

- Disconnect moonroof switch.

- Check continuity between moonroof switch terminals.

Is the inspection result normal? Yes >> moonroof switch is ok.

No >> replace moonroof switch (map lamp assembly). Refer to rf-50, "removal and installation".

Moonroof motor assembly : special repair requirement

1. Perform initialization procedure

Perform initialization procedure.

Refer to rf-18, "additional service when replacing control unit : special repair requirement".

>> Go to 2.

2. Check anti-pinch operation

Check anti-pinch operation.

Refer to rf-18, "additional service when replacing control unit : special repair requirement".

Is the inspection result normal? Yes >> inspection end.

No >> check fitting adjustment. Refer to rf-40, "adjustment".

Moonroof switch

Moonroof switch

Description

Transmits switch operation signal to moonroof motor assembly.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to RF-13, "Wiring Diagram".

1.Check moonroof sw ...

Other materials:

B00D5 Passenger air bag OFF Indicator

Description

DTC B00D5 FRONT PASSENGER AIR BAG OFF INDICATOR

The front passenger air bag off indicator is wired to the air bag diagnosis

sensor unit. The air bag diagnosis

sensor unit monitors the front passenger air bag off indicator and circuit for

failures.

PART LOCATION

Refer to SRC-5, ...

Precautions for Suspension

When installing rubber bushings, the final tightening must be carried

out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to

wipe off any spilled oil

Unladen conditions mean that fuel, engine coolant and lubricant are full. ...

Bcm branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the bcm for damage, bend and loose

connection (unit side and

connector side).

Is the inspection result normal?

Yes > ...