Nissan Sentra Service Manual: Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector E4

- Harness connector m2

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (open circuit)

- Disconnect the following harness connectors.

- Ipdm e/r

- Harness connectors E4 and M2

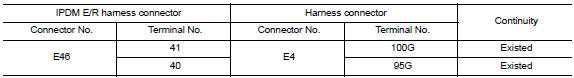

- Check the continuity between the ipdm e/r harness connector and the harness connector.

Is the inspection result normal? Yes >> go to 3.

No >> repair the main line between the ipdm e/r and the harness connector e4.

3.Check harness continuity (open circuit)

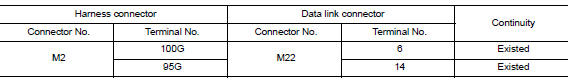

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal? Yes (present error)>>check can system type decision again.

Yes (past error)>>error was detected in the main line between the ipdm e/r and the data link connector.

No >> repair the main line between the harness connector m2 and the data link connector.

Can system (type 5)

Can system (type 5)

Dtc/circuit diagnosis ...

Main line between dlc and hvac circuit

Main line between dlc and hvac circuit

Diagnosis procedure

1.Check harness continuity (open circuit)

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Disconnect the following harness connector ...

Other materials:

Cleaning interior

This vehicle has new and unique surfaces on the

center console and door pull finishers. If cleaning

is required use mild soap and water. However if

mild soap and water won’t clean the center console

and door pull finishers, use NISSAN Vinyl

and Leather Cleaner (or equivalent).

Occasionally ...

P0713 Transmission fluid temperature sensor A

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0713

FLUID TEMP SENSOR A

(Transmission Fluid Temperature

Sensor A Circuit High)

The CVT fluid temperature identified by the

TCM is ...

Front wiper drive assembly

Exploded view

Wiper blade (RH)

Wiper arm (RH)

Wiper drive assembly

Wiper arm (LH)

Wiper blade (LH)

Removal and installation

REMOVAL

Remove the cowl top. Refer to EXT-26, "Removal and Installation".

Disconnect the harness connector from the wiper drive assembly.

...