Nissan Sentra Service Manual: Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

- Turn the ignition switch off.

- Disconnect the battery cable from the negative terminal.

- Check the following terminals and connectors for damage, bend and loose connection (connector side and harness side).

- Harness connector e4

- Harness connector m2

Is the inspection result normal? Yes >> go to 2.

No >> repair the terminal and connector.

2.Check harness continuity (open circuit)

- Disconnect the following harness connectors.

- Ipdm e/r

- Harness connectors e4 and m2

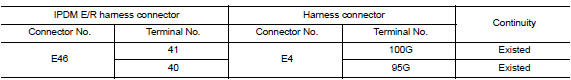

- Check the continuity between the ipdm e/r harness connector and the harness connector.

Is the inspection result normal? Yes >> go to 3.

No >> repair the main line between the ipdm e/r and the harness connector e4.

3.Check harness continuity (open circuit)

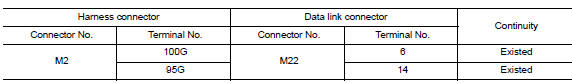

Check the continuity between the harness connector and the data link connector.

Is the inspection result normal? Yes (present error)>>check can system type decision again.

Yes (past error)>>error was detected in the main line between the ipdm e/r and the data link connector.

No >> repair the main line between the harness connector m2 and the data link connector.

Can system (type 3)

Can system (type 3)

Dtc/circuit diagnosis ...

Main line between dlc and av circuit

Main line between dlc and av circuit

Diagnosis procedure

1.Check harness continuity (open circuit)

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Disconnect the following harness connector ...

Other materials:

Removal and installation

Starter motor

Exploded View

“S” terminal harness

“B” terminal harness

Starter motor

Cylinder block

Removal and Installation

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug

openings to prevent fluid from spilling.

REMOVAL

Dis ...

Dtc/circuit diagnosis

Eco mode switch

Component function check

1. Check eco mode switch operation

Turn ignition switch on.

Check ECO mode indicator lamp turns ON/OFF on combination meter when

turn ECO mode switch ON/

OFF.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Proceed to DM ...

Ipdm-e branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ipdm e/r for damage, bend and

loose connection (unit side

and connector side).

Is the inspection result normal?

Yes ...