Nissan Sentra Service Manual: Diagnosis and repair workflow

Work Flow

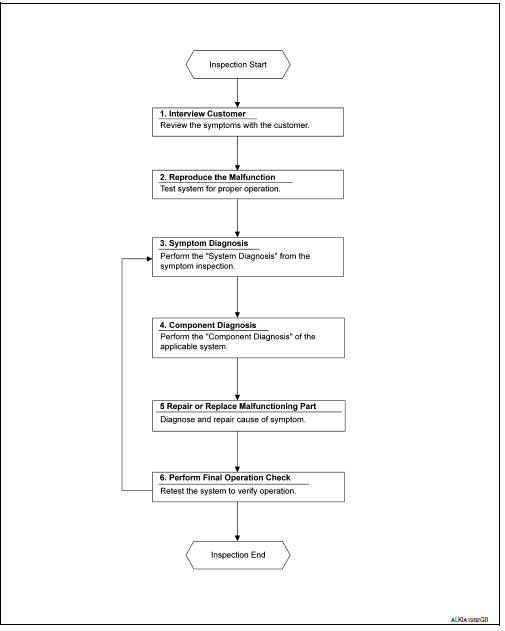

OVERALL SEQUENCE

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2. CONFIRM THE SYMPTOM

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3.

3. IDENTIFY THE MALFUNCTIONING SYSTEM WITH SYMPTOM DIAGNOSIS

Use Symptom diagnosis from the symptom inspection result in step 2 and then identify where to start performing the diagnosis based on possible causes and symptoms.

>> GO TO 4.

4. PERFORM THE COMPONENT DIAGNOSIS OF THE OF THE APPLICABLE SYSTEM

Perform the diagnosis with Component diagnosis of the applicable system.

>> GO TO 5.

5. REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6.

6. FINAL CHECK

Check that malfunctions are not reproduced when obtaining the malfunction information from the customer, referring to the symptom inspection result in step 2.

Are the malfunctions corrected? YES >> Inspection End.

NO >> GO TO 3.

Basic inspection

Basic inspection

...

Additional service when removing battery negative terminal

Additional service when removing battery negative terminal

Description

When the battery negative terminal is disconnected, the initialization is

necessary for normal operation of

power window system.

CAUTION:

The following specified operations can not b ...

Other materials:

Diagnosis system (bcm) (without intelligent

key system)

Common item

Common item : consult function (bcm -

common item)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...

Removal and installation

Hood

Hood assembly

Hood assembly : exploded view

Hood hinge (LH/RH)

Hood assembly

Hood bumper rubber

Hood seal

Hood insulator

Hood support rod

Hood support rod clamp

Clip

Hood assembly : removal and installation

CAUTION:

Use two people when removing or installing h ...

Phone settings

To access the phone settings:

Press the [ ] button.

Touch the ÔÇťSettingsÔÇŁ key.

Touch the ÔÇťPhone & BluetoothÔÇŁ key.

Touch the ÔÇťPhone SettingsÔÇŁ key and adjust

the following settings as desired:

Sort Phonebook By:

Touch ÔÇťFirst NameÔÇŁ or ÔÇťLast NameÔÇŁ to

choose ...