Nissan Sentra Service Manual: Component parts

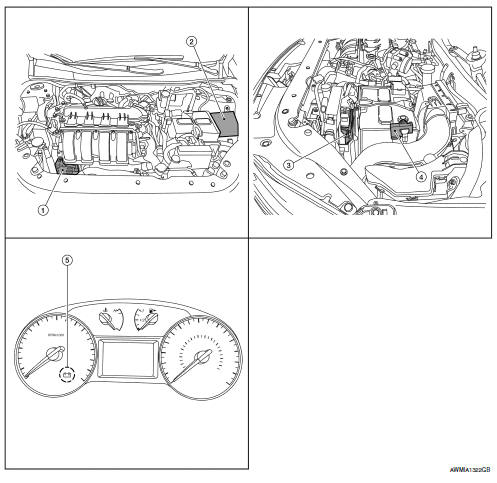

Component parts location

- Generator

- IPDM E/R (view with air inlet duct removed)

- ECM

- Battery current sensor

- Charge warning lamp indicator

Component description

| Component part | Description |

| Generator (IC regulator) | The IC regulator controls the power generation voltage

by the target

power generation voltage based on the received PWM command

signal.

When there is no PWM command signal, the generator performs the normal power generation according to the characteristic of the IC regulator. |

| IPDM E/R | The IPDM E/R converts the received power generation command value into a pulse width modulated (PWM) command signal and sends it to the IC regulator. |

| ECM | The battery current sensor detects the charging/discharging current

of the battery. The ECM judges the battery condition based on

this signal.

The ECM judges whether to request more output via the power generation voltage variable control according to the battery condition. When performing the power generation voltage variable control, the ECM calculates the target power generation voltage according to the battery condition and sends the calculated value as the power generation command value to the IPDM E/R. |

| Battery current sensor | The battery current sensor is located on the negative battery cable terminal. The battery current sensor detects the charging/discharging current of the battery and sends a voltage signal to the ECM according to the current value detected. |

| Combination meter (charge warning lamp) | The IC regulator warning function activates to illuminate the

charge warning lamp if any of the following symptoms occur while

generator is operating:

В·Excessive voltage is produced.

В·No voltage is produced. |

Charging system

Charging system

System Diagram

System Description

The generator provides DC voltage to operate the vehicle's electrical system

and to keep the battery charged.

The voltage output is controlled by the IC ...

Other materials:

Bcm branch line circuit

Diagnosis Procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the BCM for damage, bend and loose

connection (unit side and

connector side).

Is the inspection result normal?

YES > ...

Oil pan

Exploded View

O-ring

Oil pan (upper)

Oil level gauge guide

O-ring

Oil level gauge

Oil pump drive chain

Crankshaft sprocket

Oil pump sprocket

Oil pump chain tensioner

Oil pump

Drain plug

Drain plug washer

Oil pan (lower)

Oil filter

Clamp

Water hose

Oil cooler

...

Rearview mirror (if so equipped)

The night position 1 reduces glare from the

headlights of vehicles behind you at night.

Use the day position 2 when driving in daylight

hours.

WARNINGUse the night position only when

necessary,

because it reduces rear view clarity.

...