Nissan Sentra Service Manual: Charging system preliminary inspection

Diagnosis Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair battery terminal connection. Confirm repair by performing complete Charging system test using EXP-800 NI or GR8-1200 NI (if available). Refer to the applicable Instruction Manual for proper testing procedures.

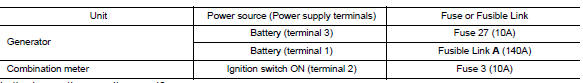

2.Check fuse

Check for blown fuse and fusible link.

Is the inspection result normal? Yes >> go to 3.

No >> replace the blown fuse or fusible link after repairing the affected circuit.

3.Check generator ground terminal connection

Check if connector f17 terminal 5 and 6 is clean.

Is the inspection result normal? Yes >> go to 4.

No >> repair connection.

4.Check drive belt tension

Check drive belt tension. Refer to chg-29, "removal and installation".

Is the inspection result normal? Yes >> inspection end.

No >> repair as needed.

Power generation voltage variable control system operation inspection

Power generation voltage variable control system operation inspection

Diagnosis Procedure

Regarding wiring diagram information. Refer to chg-9, "wiring diagram".

Caution:

When performing this inspection, always use a charged battery that has

completed the ...

Other materials:

Ecm branch line circuit

Diagnosis Procedure

1.CHECK CONNECTOR

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the ECM for damage, bend and loose

connection (unit side and

connector side).

Is the inspection result normal?

YES > ...

Wiring diagram

Sport mode system

Wiring diagram

...

Vehicle Dynamic Control (VDC) off switch

The vehicle should be driven with the Vehicle

Dynamic Control (VDC) system on for most driving

conditions.

If the vehicle is stuck in mud or snow, the VDC

system reduces the engine output to reduce

wheel spin. The engine speed will be reduced

even if the accelerator is depressed to the f ...