Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

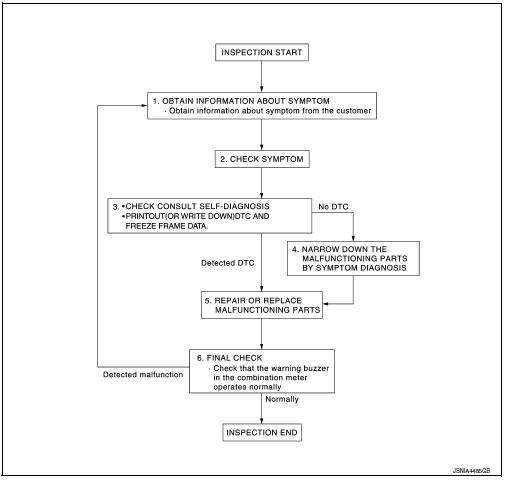

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

Connect CONSULT and perform self-diagnosis. Refer to MWI-26, "DTC Index".

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Wiring diagram

Wiring diagram

Warning chime system

Wiring diagram

...

Other materials:

NISSAN vehicle immobilizer system

The NISSAN Vehicle Immobilizer system will not

allow the engine to start without the use of the

registered key.

If the engine fails to start using a registered key

(for example, when interference is caused by

another registered key, an automated toll road

device or automatic payment device o ...

Diagnosis system (BCM) (without intelligent key system)

Common item

Common item : consult function (bcm - common item)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...

P2122, P2123 APP Sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P2122 or P2123 is displayed with DTC P0643, first perform the

trouble diagnosis for DTC P0643.

Refer to EC-353, "DTC Logic".

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible caus ...