Nissan Sentra Service Manual: Air conditioning cut control

AIR CONDITIONING CUT CONTROL : System Description

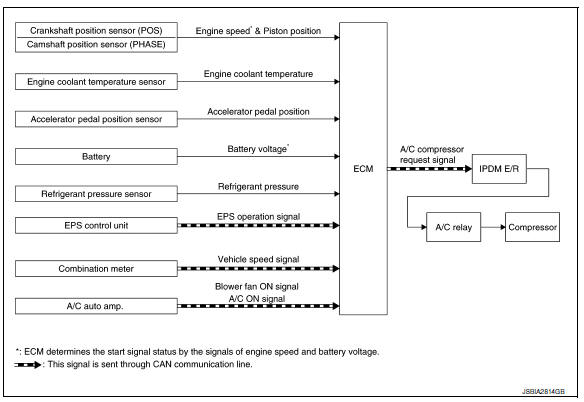

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

| Sensor | Input Signal to ECM | ECM function | Actuator | |

| Crankshaft position sensor (POS) | Engine speed* Piston position | Air conditioner cut control | IPDM E/R

↓ Air conditioner relay ↓ Compressor |

|

| Camshaft position sensor (PHASE) | ||||

| Engine coolant temperature sensor | Engine coolant temperature | |||

| Accelerator pedal position sensor | Accelerator pedal position | |||

| Battery | Battery voltage* | |||

| Refrigerant pressure sensor | Refrigerant pressure | |||

| EPS control unit | CAN communication | EPS operation signal | ||

| Combination meter | CAN communication | Vehicle speed signal | ||

| A/C auto amp. | CAN communication |

|

||

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

- When the accelerator pedal is fully depressed.

- When cranking the engine.

- At high engine speeds.

- When the engine coolant temperature becomes excessively high.

- When operating power steering during low engine speed or low vehicle speed.

- When engine speed is excessively low.

- When refrigerant pressure is excessively low or high.

Fuel filler cap warning system

Fuel filler cap warning system

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

The fuel filler cap warning system alerts the driver to the prevention of the

fuel filler being left uncapped and

malfunction occurrences after refueling, by ...

Cooling fan control

Cooling fan control

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

ECM controls cooling fan speed corresponding to vehicle speed, engine coolant

temperature, refrigerant pressure,

air conditioner ON signal. Then control syst ...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injur ...

Rear power window motor

Removal and Installation

REMOVAL

Remove the rear door glass regulator (1). Refer to GW-21,

"Removal and Installation"

Remove the screws and the rear power window motor (2).

INSTALLATION

Installation is in the reverse order of removal. ...