Nissan Sentra Service Manual: P1078 EVT Control position sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P1078 | EXH TIM SEN/CIRC-B1 (Exhaust valve timing control position sensor circuit bank 1) | An excessively high or low voltage from the sensor is sent to ECM. |

|

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for 10 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-359, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

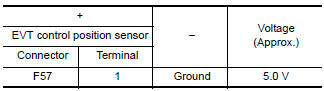

1.CHECK EXHAUST VALVE TIMING (EVT) CONTROL POSITION SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect exhaust valve timing (EVT) control position sensor harness connector.

- Turn ignition switch ON.

- Check the voltage between EVT control position sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Check sensor power supply 2 circuit. Refer to EC-444, "Diagnosis Procedure".

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

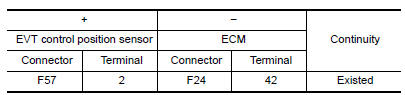

3.CHECK EVT CONTROL POSITION SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector

- Check the continuity between EVT control position sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

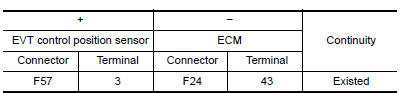

4.CHECK EVT CONTROL POSITION SENSOR INPUT SIGNAL CIRCUIT

- Disconnect ECM harness connector.

- Check the continuity between EVT control position sensor harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK EVT CONTROL POSITION SENSOR

Check the EVT control position sensor. Refer to EC-360, "Component Inspection (EVT Control Position Sensor)".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace EVT control position sensor. Refer to EM-60, "Removal and Installation".

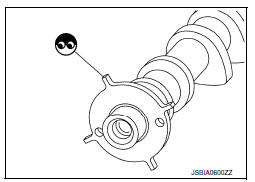

6.CHECK CAMSHAFT (EXT)

Check the following.

- Accumulation of debris to the signal plate of camshaft rear end

- Chipping signal plate of camshaft rear end

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to EM-60, "Removal and Installation".

Component Inspection (EVT Control Position Sensor)

1.EXHAUST VALVE TIMING (EVT) CONTROL POSITION SENSOR-1

- Turn ignition switch OFF.

- Disconnect EVT control position sensor harness connector.

- Loosen the fixing bolt of the sensor.

- Remove EVT control position sensor.

- Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace EVT control position sensor. Refer to EM-60, "Removal and Installation".

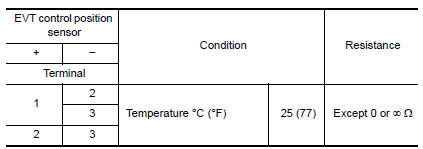

2.EVT CONTROL POSITION SENSOR-2

Check resistance EVT control position sensor terminals as shown below.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVT control position sensor. Refer to EM-60, "Removal and Installation".

P0850 PNP Switch

P0850 PNP Switch

Description

For CVT models, transmission range switch is turn ON when the selector lever

is P or N.

For M/T models, park/neutral position (PNP) range switch is ON when the selector

lever is Ne ...

P1148 Closed loop control

P1148 Closed loop control

DTC Logic

DTC DETECTION LOGIC

NOTE:

DTC P1148 is displayed with DTC for A/F sensor 1.

When the DTC is detected, perform the trouble diagnosis of DTC corresponding to

A/F sensor 1.

DTC ...

Other materials:

Power supply and ground circuit

Bcm (body control system) (with intelligent key system)

BCM (BODY CONTROL SYSTEM) (WITH INTELLIGENT KEY SYSTEM) : Diagnosis Procedure

Regarding Wiring Diagram information, refer to BCS-51, "Wiring Diagram".

1.CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link ...

CVT Oil warmer

Exploded View

Transaxle assembly

O-ring

CVT oil warmer

CVT fluid

Removal and Installation

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns

could occur from high pressure

coolant escaping from the radiator. Wrap a thick cloth around the cap ...

Removal and installation

Audio unit

Exploded view

Audio unit

Audio unit bracket (LH)

Audio unit bracket (RH)

Removal and installation

Removal

Disconnect the negative battery terminal. Refer to pg-50, "removal and

installation (battery)".

Remove cluster lid c lower. Refer to ip-20, "re ...