Nissan Sentra Service Manual: P0743 Torque converter

DTC Logic

DTC DETECTION LOGIC

| DTC | CONSULT screen terms (Trouble diagnosis content) | DTC detection condition | Possible causes |

| P0743 | TORQUE CONVERTER (Torque Converter Clutch Circuit Electrical) | The TCM torque converter clutch solenoid

valve current monitor reading is 200 mA or

less continuously for 480 msec or more under

the following diagnosis conditions: Diagnosis conditions

|

|

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE OPERATION (PART 1)

If another “DTC CONFIRMATION PROCEDURE” occurs just before, turn ignition switch OFF and wait for at least 10 seconds, then perform the next test.

>> GO TO 2.

2.PREPARATION BEFORE OPERATION (PART 2)

With CONSULT

With CONSULT

- Start the engine.

- Select “Data Monitor” in “TRANSMISSION”.

- Select “FLUID TEMP”.

- Confirm that the CVT fluid temperature is in the following range.

FLUID TEMP : 10В°C (50В°F) or more

With GST

With GST

- Start the engine.

- Set the CVT fluid to 10В°C (50В°F) or more.

NOTE:

When the ambient temperature is 20В°C (68В°F), the CVT fluid usually increases to 50 to 80В°C (122 to 176В°F) with driving in an urban area for approximately 10 minutes.

Is the CVT fluid 10В°C (50В°F) or more? YES >> GO TO 3.

NO >> 1. Warm the transaxle.

2. GO TO 3.

3.CHECK DTC DETECTION

- Drive the vehicle.

- Maintain the following conditions for 5 seconds or more.

Selector lever : “D” position

Vehicle speed : 40 km/h (25 MPH) or more

- Stop the vehicle.

- Check the first trip DTC.

Is “P0743” detected? YES >> Go to TM-187, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

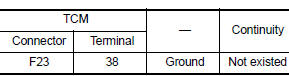

1.CHECK CIRCUIT BETWEEN TCM AND CVT UNIT

- Turn ignition switch OFF.

- Disconnect TCM connector and CVT unit connector

- Check continuity between TCM harness connector terminal and ground.

Is the check result normal? YES >> GO TO 2.

NO >> Repair or replace malfunctioning parts.

2.CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

Check torque converter clutch solenoid valve. Refer to TM-187, "Component Inspection".

Is the check result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Repair or replace malfunctioning parts.

Component Inspection

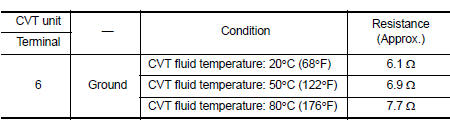

1.CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

Check resistance between CVT unit connector terminal and ground.

Is the inspection

Is the inspection

result normal?

YES >> INSPECTION END

NO >> There is a malfunction of torque converter clutch solenoid valve. Replace transaxle assembly.

Refer to TM-283, "Removal and Installation".

P0740 Torque converter

P0740 Torque converter

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0740

TORQUE CONVERTER

(Torque Converter ...

P0744 Torque converter

P0744 Torque converter

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P0744

TORQUE CONVERTER

(Torque converter ...

Other materials:

Basic inspection

Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

...

Precaution

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to th ...

Ecu diagnosis information

Ipdm e/r (intelligent power distribution module engine room)

Reference Value

Values on the diagnosis tool

Terminal layout

Physical values

Fail-safe

Can communication control

When CAN communication with ECM and BCM is impossible, IPDM E/R performs

fail-safe ...