Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

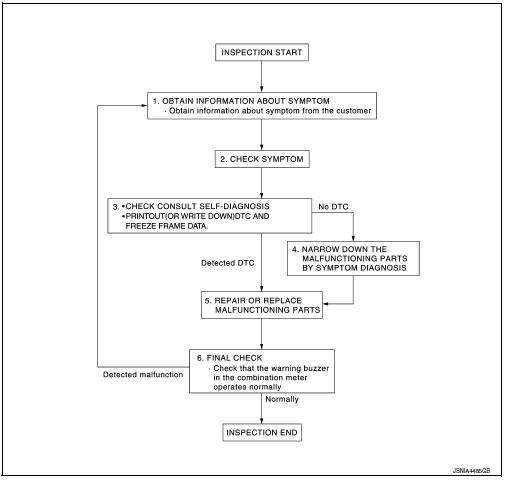

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

>> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

Connect CONSULT and perform self-diagnosis. Refer to MWI-26, "DTC Index".

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Wiring diagram

Wiring diagram

Warning chime system

Wiring diagram

...

Other materials:

CD care and cleaning

Handle a CD by its edges. Do not bend the

disc. Never touch the surface of the disc.

Always place the discs in the storage case

when they are not being used.

To clean a disc, wipe the surface from the

center to the outer edge using a clean, soft

cloth. Do not wipe the disc using ...

Front wiper drive assembly

Exploded view

Wiper blade (RH)

Wiper arm (RH)

Wiper drive assembly

Wiper arm (LH)

Wiper blade (LH)

Removal and installation

REMOVAL

Remove the cowl top. Refer to EXT-26, "Removal and Installation".

Disconnect the harness connector from the wiper drive assembly.

...

Dtc/circuit diagnosis

Malfunction area chart

Main line

Branch line

Short circuit

Main line between ipdm-e and dlc circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Check the following terminals and connectors fo ...