Nissan Sentra Service Manual: P0112, P0113 IAT Sensor

DTC Logic

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition | Possible cause |

| P0112 | IAT SEN/CIRCUIT- B1 (Intake air temperature sensor 1 circuit low bank 1) | An excessively low voltage from the intake air temperature sensor is sent to ECM. |

|

| P0113 | IAT SEN/CIRCUIT- B1 (Intake air temperature sensor 1 circuit high bank 1) | An excessively high voltage from the intake air temperature sensor is sent to ECM. |

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition switch ON and wait at least 5 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-194, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

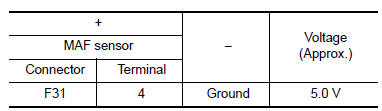

1.CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect mass air flow sensor (with intake air temperature sensor) harness connector.

- Turn ignition switch ON.

- Check the voltage between mass air flow sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

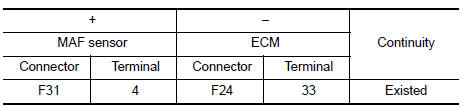

2.CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector

- Check the continuity between mass air flow sensor harness connector and ECM harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

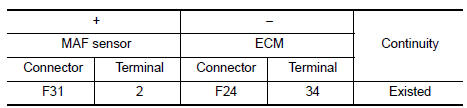

3.CHECK INTAKE AIR TEMPERATURE SENSOR GROUND CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between mass air flow sensor harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTAKE AIR TEMPERATURE SENSOR

Check the intake air temperature sensor. Refer to EC-195, "Component Inspection (IAT Sensor)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-39, "Intermittent Incident".

NO >> Replace mass air flow sensor (with intake air temperature sensor). Refer to EM-25, "Exploded View".

Component Inspection (IAT Sensor)

1.CHECK INTAKE AIR TEMPERATURE SENSOR

- Turn ignition switch OFF.

- Disconnect mass air flow sensor harness connector and reconnect it again.

- Turn ignition switch ON.

- On CONSULT screen, select “ENGINE” >> “DATA MONITOR” >> “INT/A TEMP SEN”.

- Check that the indicated value of “INT/A TEMP SEN” is almost the same as intake air temperature.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace mass air flow sensor (with intake air temperature sensor). Refer to EM-25, "Exploded View".

P0111 IAT Sensor

P0111 IAT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0111

IAT SENSOR 1 B1

(Intake air temp ...

P0116 ECT Sensor

P0116 ECT Sensor

DTC Logic

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0116

ECT SEN/CIRC

(Engine coolant tem ...

Other materials:

Diagnosis system (BCM) (with intelligent key system)

Common item

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...

Diagnosis system (bcm) (without intelligent key system)

Common item

COMMON ITEM : CONSULT Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT performs the following functions via CAN communication with BCM.

Direct Diagnostic Mode

Description

ECU identification

The BCM part number is displayed.

Self Diagnostic Result

...

Symptom diagnosis

Audio system

Symptom table

Related to audio

Related to hands-free phone

Before performing diagnosis, confirm that the cellular phone being used

by the customer is compatible with

the vehicle.

It is possible that a malfunction is occurring due to a version change

of the phone ...