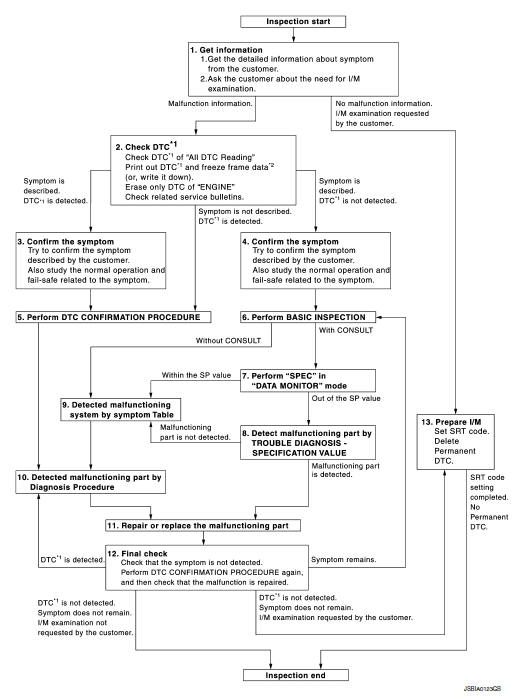

Nissan Sentra Service Manual: Diagnosis and repair workflow

Work Flow

OVERALL SEQUENCE

*1: Include 1st trip DTC.

*2: Include 1st trip freeze frame data.

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when the incident/malfunction occurred) using the “Diagnostic Work Sheet”. (Refer to EC-129, "Diagnostic Work Sheet".)

>> GO TO 2.

2.CHECK DTC

- Check DTC.

- Perform the following procedure if DTC is displayed.

- Record DTC and freeze frame data. (Print them out using CONSULT or GST.)

- Erase DTC.

With CONSULT: “How to Erase DTC

With CONSULT: “How to Erase DTC

and 1st Trip DTC” in EC-66, "CONSULT Function".

Without CONSULT: “How to Erase

Without CONSULT: “How to Erase

Self-diagnostic Results” in EC-63, "On Board Diagnosis Function".

- Study the relationship between the cause detected by DTC and the symptom

described by the customer.

(Symptom Table is useful. Refer to EC-473, "Symptom Table".)

- Check related service bulletins for information.

Is any symptom described and is any DTC detected?

Symptom is described, DTC is detected>>GO TO 3.

Symptom is described, DTC is not detected>>GO TO 4.

Symptom is not described, DTC is detected>>GO TO 5.

3.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer (except MIL ON).

Also study the normal operation and fail safe related to the symptom. Refer to EC-478, "Description" and EC- 90, "Fail Safe".

Diagnosis Work Sheet is useful to verify the incident.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5.

4.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

Also study the normal operation and fail safe related to the symptom. Refer to EC-478, "Description" and EC- 90, "Fail Safe".

Diagnosis Work Sheet is useful to verify the incident.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 6.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the displayed DTC, and then make sure that DTC is detected again.

If two or more DTCs are detected, refer to EC-93, "DTC Inspection Priority Chart" and determine trouble diagnosis order.

NOTE:

- Freeze frame data is useful if the DTC is not detected.

- Perform Component Function Check if DTC CONFIRMATION PROCEDURE is not

included on Service

Manual. This simplified check procedure is an effective alternative though

DTC cannot be detected during

this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC CONFIRMATION PROCEDURE.

Is DTC detected?

YES >> GO TO 10.

NO >> Check according to EC-94, "DTC Index".

6.PERFORM BASIC INSPECTION

Perform EC-131, "Work Procedure".

Do you have CONSULT? YES >> GO TO 7.

NO >> GO TO 9.

7.PERFORM SPEC IN DATA MONITOR MODE

With CONSULT

With CONSULT

Make sure that “MAS A/F SE-B1”, “B/FUEL SCHDL” and “A/F ALPHA-B1” are within the SP value using CONSULT in “SPEC” of “DATA MONITOR” mode. Refer to EC-157, "Component Function Check".

Is the measurement value within the SP value? YES >> GO TO 9.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART BY TROUBLE DIAGNOSIS - SPECIFICATION VALUE

Detect malfunctioning part according to EC-158, "Diagnosis Procedure".

Is malfunctioning part detected? YES >> GO TO 11.

NO >> GO TO 9.

9.DETECT MALFUNCTIONING SYSTEM BY SYMPTOM TABLE

Detect malfunctioning system according to EC-473, "Symptom Table" based on the confirmed symptom in step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 10.

10.DETECT MALFUNCTIONING PART BY DIAGNOSIS PROCEDURE

Inspect according to Diagnosis Procedure of the system.

NOTE:

The Diagnosis Procedure in EC section described based on open circuit inspection. A short circuit inspection is also required for the circuit check in the Diagnosis Procedure. For details, refer to Circuit Inspection in GI- 42, "Circuit Inspection".

Is malfunctioning part detected? YES >> GO TO 11.

NO >> Monitor input data from related sensors or check the voltage of related ECM terminals using CONSULT.

Refer to EC-77, "Reference Value".

11.REPAIR OR REPLACE THE MALFUNCTIONING PART

- Repair or replace the malfunctioning part.

- Reconnect parts or connectors disconnected during Diagnosis Procedure again after repair and replacement.

- Check DTC. If DTC is displayed, erase it. Refer to the following.

With CONSULT: “How to Erase DTC

With CONSULT: “How to Erase DTC

and 1st Trip DTC” in EC-66, "CONSULT Function".

Without CONSULT: “How to Erase

Without CONSULT: “How to Erase

Self-diagnostic Results” in EC-63, "On Board Diagnosis Function".

>> GO TO 12.

12.FINAL CHECK

When DTC was detected in step 2, perform DTC CONFIRMATION PROCEDURE or Component Function Check again, and then check that the malfunction have been completely repaired.

When symptom was described from the customer, refer to confirmed symptom in step 3 or 4, and check that the symptom is not detected.

Is DTC detected and does symptom remain? YES-1 >> DTC is detected: GO TO 10.

YES-2 >> Symptom remains: GO TO 6.

NO-1 >> No request for I/M examination from the customer: Before returning the

vehicle to the customer,

always erase unnecessary DTC in ECM and TCM (

With CONSULT: Refer to “How to

With CONSULT: Refer to “How to

Erase

DTC and 1st Trip DTC” in EC-66, "CONSULT Function",

Without CONSULT: Refer to “How to

Without CONSULT: Refer to “How to

Erase Self-diagnostic Results” in EC-63, "On Board Diagnosis Function"). If the

completion of

SRT is needed, drive vehicle under the specific driving pattern. Refer to

EC-146, "SRT Set Driving

Pattern".

NO-2 >> I/M examination, requested from the customer: GO TO 13.

13.PREPARE FOR I/M EXAMINATION

- Set SRT codes. Refer to EC-145, "Description".

- Erase permanent DTCs. Refer to EC-151, "Description".

>> INSPECTION END

Diagnostic Work Sheet

DESCRIPTION

There are many operating conditions that lead to the malfunction of engine components. A good grasp of such conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a incident. It is important to fully understand the symptoms or conditions for a customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order to organize all the information for troubleshooting.

Some conditions may cause the MIL to come on steady or blink and DTC to be detected. Examples: Vehicle ran out of fuel, which caused the engine to misfire.

Worksheet sample

Basic inspection

Basic inspection

...

Basic inspection

Basic inspection

Work Procedure

1.INSPECTION START

Check service records for any recent repairs that may indicate a related

malfunction, or a current need for

scheduled maintenance.

Open engine hood and ch ...

Other materials:

Dtc/circuit diagnosis

Power supply and ground circuit

Audio unit

Audio unit : diagnosis procedure

Regarding Wiring Diagram information, refer to AV-157, "Wiring Diagram".

1.Check fuse

Are the fuses blown?

Yes >> replace the blown fuse after repairing the affected circuit.

No >> go to 2.

...

P1588 G Sensor

DTC Logic

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

Possible causes

P1588

G Sensor

(Gravity Sensor Circuit)

When the following diagnosis conditions are

satisfied and the detection conditi ...

Loading tips

The GVW must not exceed GVWR

or GAWR as specified on the

F.M.V.S.S./C.M.V.S.S. certification

label.

Do not load the front and rear axle to

the GAWR. Doing so will exceed the

GVWR.

WARNING

Properly secure all cargo with

ropes or straps to help prevent it

from slid ...