Nissan Sentra Service Manual: Corrosion protection

Description

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-corrosive measures.

Anti-Corrosive Wax

To improve repairability and corrosion resistance, a new type of anticorrosive precoated steel sheet has been adopted replacing conventional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron alloy, which provides excellent and long term corrosion resistance with cationic electrodeposition primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive performance built into the vehicle at the factory.

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodeposition primer, which provide excellent corrosion protection, are employed on all body components.

CAUTION:

Confine paint removal during welding operations to an absolute minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain anti-corrosive performance built into the vehicle at the factory.

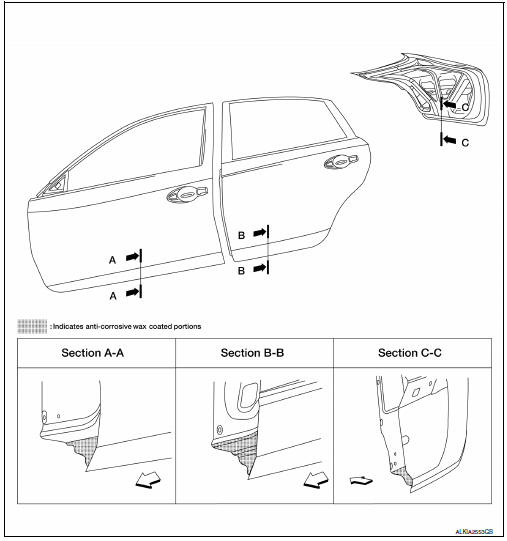

Anti-Corrosive Wax

To improve corrosion resistance, anti-corrosive wax is applied inside the body sill and inside other closed sections.

Accordingly, when replacing these parts, be sure to apply anti-corrosive wax to the appropriate areas of the new parts. Select an excellent anti-corrosive wax which will penetrate after application and has a long shelf life.

Front

Front

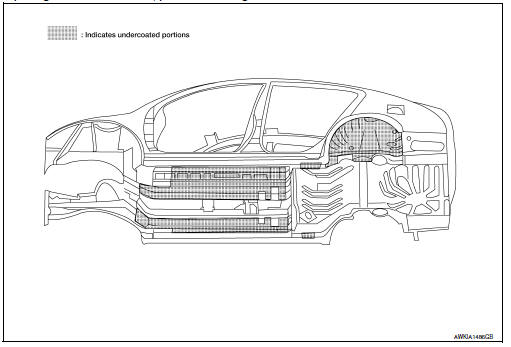

Undercoating

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chipping.

Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoating which is rust preventive, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

- Do not apply undercoating to any place unless specified (such as the areas above the muffler and three way catalyst which are subjected to heat).

- Do not undercoat the exhaust pipe or other parts which become hot.

- Do not undercoat rotating parts.

- Apply bitumen wax after applying undercoating

- After putting seal on the vehicle, put undercoating on it.

Body sealing

Body sealing

Description

The following figure shows the areas which are sealed at the factory. Sealant

which has been applied to these

areas should be smooth and free from cuts or gaps. Care should be taken no ...

Other materials:

Cylinder block

Exploded View

Cylinder block

Block heater (for Canada)

Top ring

Second ring

Oil ring

Piston

Piston pin

Snap ring

Connecting rod

Connecting rod bearing (upper)

Connecting rod bearing (lower)

Crankshaft key

Connecting rod cap

Connecting rod cap bolt

Main bearing ca ...

Precaution

Precaution for supplemental restraint system (srs) "air bag" and "seat

belt pre-tensioner"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injur ...

P0014 EVT control

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0014 is displayed with DTC P0078, first perform trouble

diagnosis for DTC P0078. Refer to

EC-183, "DTC Logic".

If DTC P0014 is displayed with P1078, first perform trouble diagnosis

for P1078. Refer to EC-359,

"DTC Logic&quo ...