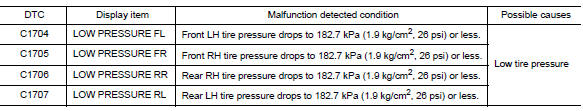

Nissan Sentra Service Manual: C1704, C1705, C1706, C1707 Low tire pressure

DTC Logic

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II User Guide for additional information.

- Activate and display TPMS transmitter IDs

- Display tire pressure reported by the TPMS transmitter

- Read TPMS DTCs

- Register TPMS transmitter IDs

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

With CONSULT

With CONSULT

- Turn the ignition switch ON.

- Check the tire pressure for all wheels and adjust to the specified value. Refer to WT-54, "Tire Air Pressure".

- Perform “SELF DIAGNOSTIC RESULT”.

Is DTC “C1704”, “C1705”, “C1706”, or “C1707” detected? YES >> Proceed to WT-25, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following functions. Refer to the Signal Tech II User Guide for additional information.

- Activate and display TPMS transmitter IDs

- Display tire pressure reported by the TPMS transmitter

- Read TPMS DTCs

- Register TPMS transmitter IDs

1.CHECK DATA MONITOR

With CONSULT

With CONSULT

- Drive for 3 minutes at a speed of 40 km/h (25 MPH) or more, then drive normally for 10 minutes.

- Stop the vehicle.

- On “DATA MONITOR” select “AIR PRESS FL”, “AIR PRESS FR”, “AIR PRESS RR” and “AIR PRESS RL”..

- Within 5 minutes after vehicle stopped, check that the tire pressures are within specification. Refer to WT- 54, "Tire Air Pressure".

| Monitor item | Displayed value |

| AIR PRESS FL | Approximately equal to value indicated on tire gauge for front LH tire |

| AIR PRESS FR | Approximately equal to value indicated on tire gauge for front RH tire |

| Monitor item | Displayed value |

| AIR PRESS RR | Approximately equal to value indicated on tire gauge for rear RH tire |

| AIR PRESS RL | Approximately equal to value indicated on tire gauge for rear LH tire |

Is the inspection result normal? YES >> Inspection End.

NO >> Repair or replace malfunctioning components.

C1708, C1709, C1710, C1711 Transmitter (no data)

C1708, C1709, C1710, C1711 Transmitter (no data)

DTC Logic

NOTE:

The Signal Tech II Tool (J-50190) can be used to perform the following

functions. Refer to the Signal Tech II

User Guide for additional information.

Activate and display TPMS ...

Other materials:

Moonroof switch

Removal and installation

REMOVAL

Remove the map lamp. Refer to INL-52, "Removal and Installation".

Release the pawls and remove the moonroof switch finisher (1).

: Pawl

Release the pawls and remove the moonroof switch (2).

: Pawl

INSTALLATION

Installation is in the ...

Diagnosis description : permanent diagnostic

trouble code (permanent DTC)

Permanent DTC is defined in SAE J1979/ISO 15031-5 Service $0A.

ECM stores a DTC issuing a command of turning on MIL as a permanent DTC and

keeps storing the DTC as

a permanent DTC until ECM judges that there is no presence of malfunction.

Permanent DTCs cannot be erased by using the erase f ...

Basic inspection

Diagnosis and repair work flow

Work flow

OVERALL SEQUENCE

DETAILED FLOW

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the

condition and the environment when

the incident/malfunction occurs).

Check operation condition of the function th ...