Nissan Sentra Service Manual: C1140 Actuator relay system

DTC Logic

DTC DETECTION LOGIC

| DTC | Display Item | Malfunction detected condition | Possible causes |

| C1140 | ACTUATOR RLY | When a malfunction is detected in actuator relay. |

|

DTC CONFIRMATION PROCEDURE

1.CHECK SELF DIAGNOSTIC RESULT

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Perform self diagnostic result.

Is DTC C1140 detected? YES >> Proceed to diagnosis procedure. Refer to BRC-77, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to BRC-44, "Wiring Diagram".

1.CONNECTOR INSPECTION

-

Turn ignition switch OFF.

-

Disconnect ABS actuator and electric unit (control unit) connector.

-

Check connector and terminals for deformation, disconnection, looseness or damage.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.Check ABS Actuator and electric unit (control unit) battery power supply

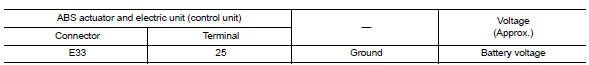

Check voltage between ABS actuator and electric unit (control unit) connector E33 terminal 25 and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace malfunctioning components.

3.Check abs actuator and electric unit (control unit) ground circuit

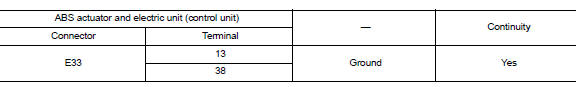

Check continuity between ABS actuator and electric unit (control unit) connector E33 terminals 13, 38 and ground.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-110, "Removal and Installation".

NO >> Repair or replace malfunctioning components.

C1130 Engine signal

C1130 Engine signal

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1130

ENGINE SIGNAL 1

When a malfunction is detected in ECM system.

...

C1142 Press sensor

C1142 Press sensor

DTC Logic

DTC DETECTION LOGIC

DTC

Display Item

Malfunction detected condition

Possible causes

C1142

PRESS SEN CIRCUIT

When a malfunction is detected in master cylinde ...

Other materials:

Auto operation does not operate but manual operate normally (driver side)

Diagnosis Procedure

1.PERFORM INITIALIZATION PROCEDURE

Initialization procedure is executed and operation is confirmed.

Refer to PWC-29, "Work Procedure".

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK ENCODER CIRCUIT

Check encoder cir ...

System description

DESCRIPTION

Engine Cooling System Schematic

CVT Models

Radiator

Water inlet

Reservoir tank

Thermostat

Engine oil cooler

Thermostat housing

Water pump

Cylinder head

Cylinder block

Water control valve

Water outlet

Heater

Electric throttle control actuator

CVT oil wa ...

Fog light switch (if so equipped)

To turn the fog lights on, turn the headlight switch

to the position, then turn the

fog light

switch to the position.

If the headlight switch is in the AUTO position

and the fog light switch is moved to the ON

position, both the fog lights and the headlights

(including all other ...