Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

Work Flow

Detailed flow

1.Interview from the customer

Clarify customer complaints before inspection. First of all, perform an interview utilizing stc-20, "diagnostic work sheet" and reproduce symptoms as well as fully understand it. Ask customer about his/her complaints carefully. Check symptoms by driving vehicle with customer, if necessary.

Caution:

Customers are not professional. Never guess easily like “maybe the customer means that...,” Or “maybe the customer mentions this symptom”.

>> Go to 2.

2.Check symptom

Reproduce the symptom that is indicated by the customer, based on the information from the customer obtained by interview. Also check that the symptom is not caused by protection function. Refer to STC-13, "Protection Function".

Caution:

When the symptom is caused by normal operation, fully inspect each portion and obtain the understanding of customer that the symptom is not caused by a malfunction.

>> Go to 3.

3.Perform self-diagnosis

With consult

With consult

Perform self-diagnosis.

Is any dtc detected? Yes >> record or print dtc and freeze frame data (ffd). Go to 4.

No >> go to 6.

4.Recheck symptom

With consult

With consult

-

Erase self-diagnostic results.

-

Perform dtc confirmation procedures for the malfunctioning system.

Note:

If some DTCs are detected at the same time, determine the order for performing the diagnosis based on STC- 14, "DTC Inspection Priority Chart".

Is any dtc detected? Yes >> go to 5.

No >> check harness and connectors based on the information obtained by interview. Refer to gi-39, "intermittent incident".

5.Repair or replace malfunctioning parts

-

Repair or replace malfunctioning parts

-

Reconnect part or connector after repairing or replacing.

-

When dtc is detected, erase self-diagnostic results for “eps”.

>> Go to 7.

6.Identify malfunctioning system by symptom diagnosis

Estimate malfunctioning system based on symptom diagnosis and perform inspection.

Can the malfunctioning system be identified?

Yes >> go to 7.

No >> check harness and connectors based on the information obtained by interview. Refer to gi-39, "intermittent incident".

7.Final check

With consult

With consult

-

Check the reference value for eps control unit.

-

Recheck the symptom and check that symptom is not reproduced on the same conditions.

Is the symptom reproduced? YES >> GO TO 3.

NO >> Inspection End.

Diagnostic Work Sheet

Description

-

In general, customers have their own criteria for a problem. Therefore, it is important to understand the symptom and status well enough by asking the customer about his/her concerns carefully. To systemize all the information for the diagnosis, prepare the interview sheet referring to the interview points.

-

In some cases, multiple conditions that appear simultaneously may cause a dtc to be detected.

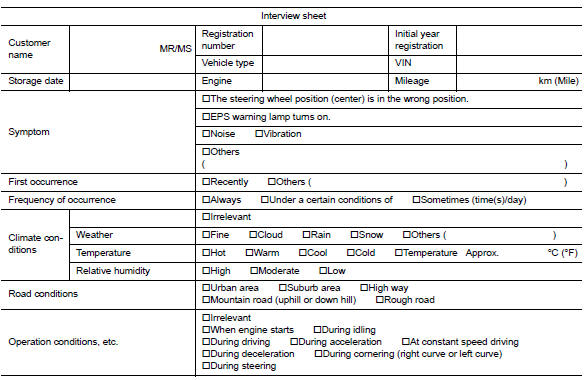

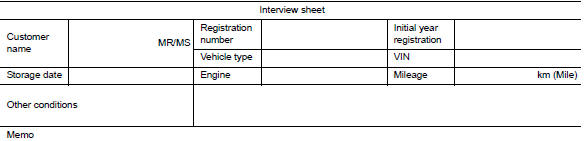

Interview sheet sample

Wiring diagram

Wiring diagram

Power steering control system

Wiring Diagram

...

Other materials:

Vehicle loading information

WARNING

It is extremely dangerous to ride

in a cargo area inside a vehicle. In

a collision, people riding in these

areas are more likely to be seriously

injured or killed.

Do not allow people to ride in any

area of your vehicle that is not

equipped with seats a ...

Component parts

STARTING SYSTEM (WITH INTELLIGENT KEY)

Component Parts Location

Starter motor

Transmission range switch (CVT Models)

IPDM E/R (view with air inlet duct

removed)

Clutch interlock switch (M/T Models)

ECM

BCM (view under instrument panel,

left side of vehicle)

Component Descri ...

Can communication circuit

Diagnosis procedure

1.Connector inspection

Turn the ignition switch off.

Disconnect the battery cable from the negative terminal.

Disconnect all the unit connectors on CAN communication system.

Check terminals and connectors for damage, bend and loose connection.

Is the inspection resu ...