Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

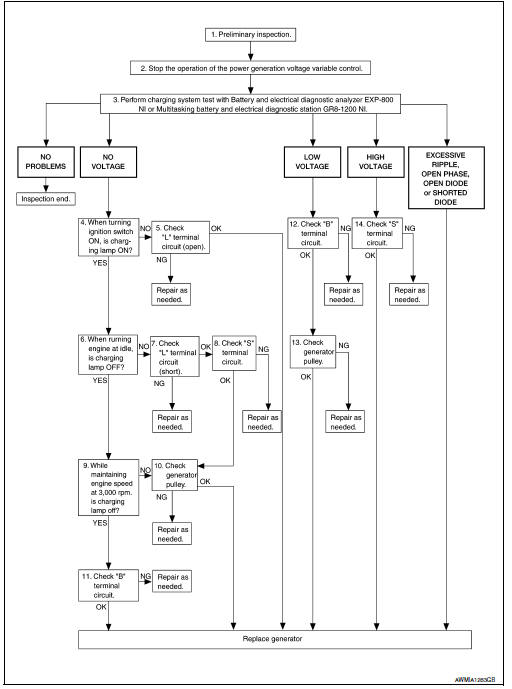

Work flow (with exp-800 ni or gr8-1200 ni)

CHARGING SYSTEM DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

To test the charging system, use the following special service tools:

- EXP-800 NI Battery and electrical diagnostic analyzer

- GR8-1200 NI Multitasking battery and electrical diagnostic station

NOTE:

Refer to the applicable Instruction Manual for proper charging system diagnosis procedures.

Revision:

OVERALL SEQUENCE

DETAILED FLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, stater and generator test segments must be done as a set from start to finish.

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-20, "Diagnosis Procedure".

>> GO TO 2.

2.STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures.

- After selecting “ENGINE” using CONSULT, set the DUTY value of “ALTERNATOR DUTY” to 0 % by selecting “ALTERNATOR DUTY” of “Active Test”. Continue “Active Test” until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the generator.)

- Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550– P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connector and erase the self diagnosis results history of the engine using CONSULT.]

>> GO TO 3.

3.DIAGNOSIS WITH EXP-800 NI OR GR8-1200 NI

Perform the charging system test using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI. Refer to the applicable Instruction Manual for proper testing procedures.

Test result

NO PROBLEMS>>Charging system is normal and will also show “DIODE RIPPLE” test result.

NO VOLTAGE>>GO TO 4.

LOW VOLTAGE>>GO TO 12.

HIGH VOLTAGE>>GO TO 14.

EXCESSIVE RIPPLE, OPEN PHASE, OPEN DIODE or SHORTED DIODE>>Replace the generator. Refer to CHG-29, "Removal and Installation". Perform “DIODE RIPPLE” test again using Multitasking battery and electrical diagnostic station GR8-1200 NI or Battery and electrical diagnostic analyzer EXP-800 NI to confirm repair.

4.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS ON)

Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> GO TO 6.

NO >> GO TO 5.

5.“L” TERMINAL CIRCUIT (OPEN) INSPECTION

Check “L” terminal circuit (open). Refer to CHG-24, "Diagnosis Procedure".

Is the “L” terminal circuit normal? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> Repair as needed.

6.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle.

Does the charge warning lamp turn OFF? YES >> GO TO 9.

NO >> GO TO 7.

7.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check “L” terminal circuit (short). Refer to CHG-26, "Diagnosis Procedure".

Is the “L” terminal circuit normal? YES >> GO TO 8.

NO >> Repair as needed.

8.“S” TERMINAL CIRCUIT INSPECTION

Check “S” terminal circuit. Refer to CHG-27, "Diagnosis Procedure".

Is the “S” terminal circuit normal? YES >> GO TO 10.

NO >> Repair as needed.

9.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 3,000 RPM)

Increase and maintain the engine speed at 3,000 rpm.

Does the charge warning lamp remain off? YES >> GO TO 11.

NO >> GO TO 10.

10.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to CHG-30, "Inspection".

Is generator pulley normal? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> Repair as needed.

11.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-23, "Diagnosis Procedure".

Is “B” terminal circuit normal? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> Repair as needed.

12.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-23, "Diagnosis Procedure".

Is “B” terminal circuit normal? YES >> GO TO 13.

NO >> Repair as needed.

13.INSPECTION OF GENERATOR PULLEY

Check generator pulley. Refer to CHG-30, "Inspection".

Is generator pulley normal? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> Repair as needed.

14.“S” TERMINAL CIRCUIT INSPECTION

Check “S” terminal circuit. Refer to CHG-27, "Diagnosis Procedure".

Is the “S” terminal circuit normal? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> Repair as needed.

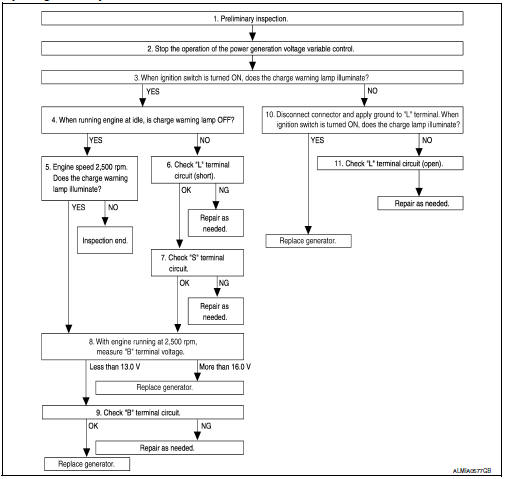

Work flow (without exp-800 ni or gr8-1200 ni).

OVERALL SEQUENCE

Before performing a generator test, make sure that the battery is fully charged. A 30-volt voltmeter and suitable test probes are necessary for the test.

- Before starting, inspect the fusible link.

- Use fully charged battery.

DETAILED FLOW

1.PRELIMINARY INSPECTION

Perform the preliminary inspection. Refer to CHG-20, "Diagnosis Procedure".

>> GO TO 2.

2.STOP POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

Stop the operation of the power generation voltage variable control in either of the following procedures:

- After selecting “ENGINE” using CONSULT, set the DUTY value of “ALTERNATOR DUTY” to 0 % by selecting “ALTERNATOR DUTY” with “Active Test”. Continue “Active Test” until the end of inspection. (When the DUTY value is 0 or 100 %, the normal power generation is performed according to the characteristic of the IC regulator of the generator.)

- Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC (P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current sensor connector and erase the self-diagnostic results history of the engine using CONSULT.]

>> GO TO 3.

3.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH IS TURNED ON)

When ignition switch is turned ON.

Does the charge warning lamp illuminate?

YES >> GO TO 4.

NO >> GO TO 10.

4.INSPECTION WITH CHARGE WARNING LAMP (IDLING)

Start the engine and run it at idle

Does the charge warning lamp turn OFF? YES >> GO TO 5.

NO >> GO TO 6.

5.INSPECTION WITH CHARGE WARNING LAMP (ENGINE AT 2,500 RPM)

Increase and maintain the engine speed at 2,500 rpm.

Does the charge warning lamp illuminate? YES >> GO TO 8.

NO >> Inspection End.

6.“L” TERMINAL CIRCUIT (SHORT) INSPECTION

Check terminal “L” circuit for (short). Refer to CHG-26, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair as needed.

7. “S” TERMINAL CIRCUIT INSPECTION

Check terminal “S” circuit. Refer to CHG-27, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair as needed.

8.MEASURE “B” TERMINAL VOLTAGE

Start engine. With engine running at 2,500 rpm, measure “B” terminal voltage.

What voltage does the measurement result show? Less than 13.0 V>>GO TO 9.

More than 16.0 V>>Replace generator. Refer to CHG-29, "Removal and Installation".

9.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to CHG-23, "Diagnosis Procedure".

Is the inspection result normal? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> Repair as needed.

10.INSPECTION WITH CHARGE WARNING LAMP (IGNITION SWITCH

IS ON)

- Disconnect generator connector and apply ground to “L” terminal.

- Turn the ignition switch ON.

Does the charge warning lamp illuminate? YES >> Replace generator. Refer to CHG-29, "Removal and Installation".

NO >> GO TO 11.

11.CHECK “L” TERMINAL CIRCUIT (OPEN)

Check “L” terminal circuit (OPEN). Refer to CHG-26, "Diagnosis Procedure".

>> Repair as needed.

Wiring diagram

Wiring diagram

Charging system

Wiring Diagram

...

Other materials:

Strg branch line circuit

Diagnosis Procedure

1.Check connector

Turn the ignition switch off

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the steering angle sensor for

damage, bend and loose connection

(unit side and connector side).

Is the inspection result ...

Audible reminders

Brake pad wear warning

The disc brake pads have audible wear warnings.

When a disc brake pad requires replacement, it

makes a high pitched scraping sound when the

vehicle is in motion, whether or not the brake

pedal is depressed. Have the brakes checked as

soon as possible if the warning sou ...

Towing a trailer

Do not tow a trailer with your vehicle.

Flat towing

Towing your vehicle with all four wheels on the

ground is sometimes called flat towing. This

method is sometimes used when towing a vehicle

behind a recreational vehicle, such as a motor

home.

CAUTION

Failure to follow these guidelines c ...