Nissan Sentra Service Manual: Basic inspection

Diagnosis and repair workflow

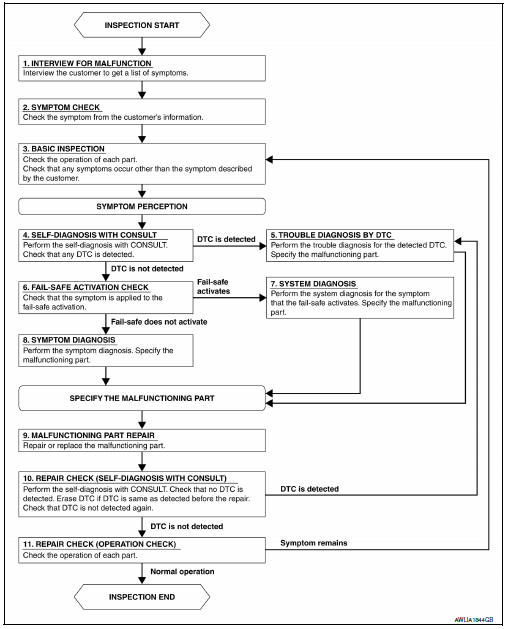

Work flow

OVERALL SEQUENCE

DETAILED FLOW

1.INTERVIEW FOR MALFUNCTION

Find out what the customer's concerns are.

>> GO TO 2.

2.SYMPTOM CHECK

Verify the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any concerns occur other than those mentioned in the customer interview.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT

Perform the self-diagnosis with CONSULT. Check that any DTC is detected.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Determine if the customer's concern is related to fail-safe activation.

Does the fail-safe activate? YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system in which the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis, refer to INL-51, "Symptom Table". Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT)

Perform the self-diagnosis with CONSULT. Verify that no DTCs are detected. Erase all DTCs detected prior to the repair. Verify that DTC is not detected again.

Is any DTC detected? YES >> GO TO 5.

NO >> GO TO 11.

11.REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 3.

Wiring diagram

Wiring diagram

Interior room lamp control system

Wiring diagram

Illumination

Wiring diagram

...

Other materials:

Maintenance precautions

When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed.

WARNING

Park the vehicle on a level surface, apply

...

Wiring diagram

Display audio with bose

Wiring diagram

...

Excessive abs function operation

frequency

Diagnosis Procedure

1.CHECK START

Check front and rear brake force distribution using a brake

tester.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check brake system.

2.CHECK FRONT AND REAR AXLE

Make sure that there is no excessive play in the front and rear

axles. ...