Nissan Sentra Service Manual: Spark plug

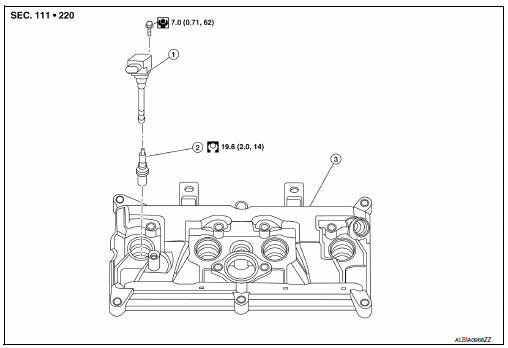

Exploded View

- Ignition coil

- Spark plug

- Rocker cover

Removal and Installation

REMOVAL

- Remove engine cover. Refer to EM-24, "Exploded View".

- Remove ignition coil. Refer to EM-46, "Exploded View".

- Remove spark plug using suitable tool.

(a) : 14 mm (0.55 in)

CAUTION:

Do not drop or shock spark plug.

INSTALLATION

Installation is in the reverse order of removal.

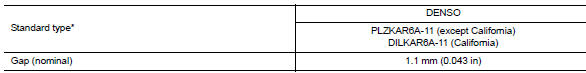

*: Always check with the Parts Department for the latest parts information.

CAUTION:

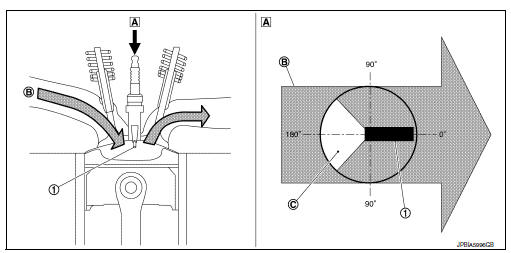

Always tighten the spark plug to specified torque to align the orientation of electrodes. The ground electrode of a genuine spark plug is positioned in the area of maximum ignitability by tightening to the specified torque. When replacing spark plugs, use genuine spark plugs of which the ground electrode is adjusted.

NOTE:

The ground electrode of the spark plug is positioned in the area of maximum ignitability to improve combustion efficiency in the cylinder, reduce CO2 (carbon dioxide) emission and improve fuel economy.

- Ground electrode of spark plug

- Top view

- Air-fuel mixture flow

- Poor ignitability region

Inspection

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

Spark plug (Standard type) : Refer to EM-118, "Spark Plug".

CAUTION:

- Do not drop or shock spark plug.

- Do not use a wire brush for cleaning.

- If plug tip is covered with carbon, spark plug cleaner may be used.

Cleaner air pressure : Less than 588 kPa (6 kg/cm2, 85 psi)

Cleaning time : Less than 20 seconds

- Spark plug gap adjustment is not required between replacement intervals.

- Measure spark plug gap. when it exceeds the limit, replace

spark plug even if it is with in the specified replacement mileage.

Refer to EM-118, "Spark Plug".

Drive belt

Drive belt

Exploded View

Alternator

Drive belt auto-tensioner

Crankshaft pulley

A/C compressor

Water pump

Drive belt

Possible use range

New drive belt range

Indicator

Removal and ...

Other materials:

Strg branch line circuit

Diagnosis procedure

1.Check connector

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Check the terminals and connectors of the steering angle sensor for

damage, bend and loose connection

(unit side and connector side).

Is the inspection result ...

Removal and installation

Combination meter

Exploded view

Combination meter

Front cover

Removal and installation

Removal

Remove cluster lid a. Refer to ip-19, "removal and installation".

Remove the screws from the combination meter.

Remove the combination meter.

Disconnect the comb ...

Vehicle loading information

WARNING

It is extremely dangerous to ride

in a cargo area inside a vehicle. In

a collision, people riding in these

areas are more likely to be seriously

injured or killed.

Do not allow people to ride in any

area of your vehicle that is not

equipped with seats a ...